Nội dung toàn văn Decision No. 12/2008/QD-BCT national technical regulation on electrical safety

MINISTRY OF INDUSTRY | SOCIALIST REPUBLIC OF VIETNAM |

No. 12/2008/QD-BCT | Hanoi, June 17, 2008 |

DECISION

TO PROMULGATE THE NATIONAL TECHNICAL REGULATION ON ELECTRICAL SAFETY

THE MINISTER OF INDUSTRY AND TRADE

Pursuant to the Government's Decree No. 189/2007/ND-CP dated December 27, 2007 on defining the functions, tasks, powers and organizational structure of the Ministry of Industry and Trade;

Pursuant to the Law on Technical regulations and standards dated June 29, 2006; the Government's Decree No. 127/2007/ND-CP dated August 01 2007 detailing the implementation of a number of articles of the Law on Technical regulations and standards;

Pursuant to the Circular No. 23/2007/TT-BKHCN dated September 28, 2007 of the Ministry of Science and Technology providing guidance on the formulation, assessment, and issuance of technical regulations;

At the request of the Director of the Industrial Safety Techniques and Environment Agency,

DECIDES:

Article 1. To promulgate the National Technical Regulation on Electrical Safety QCVN01:2008/BCT together with this Decision. This Regulation supersedes the Regulations from II TCN-161-84 to II TCN-167-84 on safety techniques of power plants and electrical grid that are promulgated together with the Decision No. 25 DL/KT dated January 22, 1985 of the Ministry of Electricity.

Article 2. This Decision takes effect after 15 days from the day on which it is published on the Official Gazette and is applicable nationwide.

Article 3. Chief of the Ministry Office, the Chief Inspector of the Ministry, Directors of Departments affiliated to the Ministry, Directors of Services of Industry and Trade of central-affiliated cities and provinces, organizations and individuals concerned are responsible for the implementation of this Decision./.

| THE MINISTER |

QCVN 01:2008/BCT

NATIONAL TECHNICAL REGULATION

ON ELECTRICAL SAFETY

Foreword

The National Technical Regulation on Electrical Safety (QCVN01:2008/BCT) is submitted by the Department of Safety Engineering and Industrial Environment, promulgated by the Ministry of Industry and Trade together with the Decision No. 12/2008/QD-BCT dated June 17, 2008.

QCVN01:2008/BCT provides for safety principles when working with power lines and electrical equipment.

NATIONAL TECHNICAL REGULATION

ON ELECTRICAL SAFETY

(Promulgated together with the Decision No. 12/2008/QD-BCT dated June 17, 2008 of the Minister of Industry and Trade)

Chapter I.

GENERAL PROVISIONS

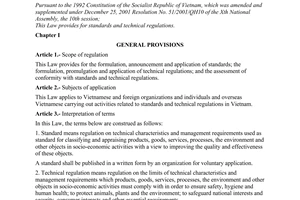

Article 1. Scope of regulation

This Regulation provides for the safety measures before carrying out construction, operation, experiments, and repair of power lines, electrical equipment, and other works according to law.

Article 2. Subjects of application

This Regulation is obligatory for all organizations and individuals that participate in electrical works and use electricity for production within Vietnam’s territory.

Article 3. Obligations of organizations and individuals that participate in electrical works and use electricity

1. Comply with this Regulation and other safety regulations relating to their assigned works.

2. Employers shall:

a) Ensure the safety conditions and provide personal safety equipment for on-site employees and ensure safety for the community.

b) Provide training in necessary knowledge about safety for employees according to law.

c) Inspect on-site safety measures.

3. When an organization or individual hires another organization or another individual to do the works that might lead to electrical accidents, both parties must reach an agreement that specifies the safety measures and obligations of each party before carrying out the works.

Article 4. Interpretation of terms

In this Regulation, the terms below are construed as follows:

1. Employer is:

a) The owner of the facility or a person authorized by the to run the production or business, or

b) The Director or Deputy Director of the facility; the Director of the organization or unit that directly manage and employ workers, or

c) A manager of a construction site, a workshop, or an equivalent unit.

2. General Commander is the person that directs the work that is carried out by multiple teams of the same electricity agency.

3. Direct Commander is the person in charge of giving assignments, directing and supervising their workers throughout the operation.

4. Authorizer is the person that allows the work team to enter the site when electrical safety at the site is assured.

5. Electrical safety supervisors are persons proficient in electrical safety that are appointed by the work team to supervise the electrical safety.

6. Watchmen are persons appointed to monitor and give warnings about the worksite safety to the public.

7. Work team is a team that undertakes works such as repairs, experiments, construction, etc.

8. Managing unit is the unit in charge of the management and operation of power lines and electrical equipment.

9. Workers are employees of the work team who directly undertake the works assigned by the direct commander.

10. Working live means working with energized devices using specialized equipment and tools.

11. Working de-energized means working with electrical equipment that have been disconnected from every source of supply.

12. Personal safety equipment is equipment used by workers to prevent accidents for themselves.

13. Electrical equipment and materials are machinery, tools, and equipment that use electricity; conductive materials, insulating materials; supporting structures used for electricity supply.

14. Specialized vehicles are vehicles provided with equipment for special purposes.

15. Disconnect means isolating the energized parts from the power supply.

16. Low-voltage electrical equipment is energized equipment with a voltage of below 1,000 volts.

17. High-voltage electrical equipment is energized equipment with a voltage of 1,000 volts or above.

Chapter II.

ESTABLISHMENT OF THE WORKING SITE

Section 1. INSTALLATION OF BARRIERS, SIGNS, AND SIGNALS

Article 5. Warnings

Barriers, signs, and signals shall be installed at hazardous areas to give send danger signals.

Article 6. Outdoor equipment

For the high-voltage electrical equipment installed outdoors, the employer shall take the following measures to prevent unauthorized people from entering the restricted area:

1. Barricading.

2. Placing the “No entry” sign at the entry and exit.

3. Locking doors or using similar tools at the entry and exit.

Article 7. Indoor equipment

For the high-voltage electrical equipment installed indoors, the employer shall take the following measures to prevent people, except for workers of the work team and their operators, from getting close to them.

Article 8. Putting up barriers around the working site

Barriers must be put up around the working site of the work team, of which the distance to surrounding energized parts does not reach the measurements in the table below, to separate the working zone from the energized part.

Voltage (kV) | Distance (m) |

Up to 15 | 0.7 |

Above 15 to 35 | 1.0 |

Above 35 to 100 | 1.5 |

220 | 2.5 |

500 | 4.5 |

The distance from the barrier to the energized part is specified below:

Voltage (kV) | Distance (m) |

Up to 15 | 0.35 |

Above 15 to 35 | 0.6 |

Above 35 to 110 | 1.5 |

220 | 2.5 |

500 | 4.5 |

Article 9. Arrangement of the worksite

During the work, all equipment and materials must be put tidily to avoid hurting people.

Article 10. Lighting at working positions

1. The employer must sustain the light intensity at working position in conformity with regulations.

2. The employer must ensure that the lighting is not dazzling or causing too much contrast.

Article 11. On-site warnings

The direct commander of the work team shall put up warning signs at dangerous areas during the work to ensure safety for workers and the community.

Section 2. ASSURANCE OF PUBLIC SAFETY

Article 12. Putting up barriers

The work team shall take appropriate measures such as putting up barriers around the working site to prevent unauthorized people from entering and causing accidents or hurting themselves. Especially when working with underground cables, the work team shall take measures to prevent people from falling into the opening.

Article 13. Warning signs

The work team must put up warning signs before working to ensure safety for the community.

Article 14. Working on the road

1. When carrying out works such as construction and repairs on the road, the work team may restrict the traffic of vehicles and passengers to ensure safety for the community.

2. Comply with the regulations of relevant functional authorities when restricting the traffic, comply with the following requirements:

a) Put up warning signs and appoint people to instruct vehicles and passengers to avoid causing danger to the community;

b) The width of the road for road vehicles to go through must be conformable with the regulations of road management authorities.

3. Put up temporary barriers and direction signs when restricting passengers to ensure the safe traffic.

4. When working near railroads, road, waterways or intersection between the power line and the road, the work team shall request the agencies concerned to appoint people to assist in the assurance of safety for vehicles and passengers, if necessary.

Chapter III.

WORK TEAM

Section 1. ORGANIZATION OF THE WORK TEAM

Article 15. Organization of the work team

A work team must have at least two people; one of them is the direct commander.

Article 16. Appointment of the direct commander and workers

The employer shall appoint suitable direct commander and workers that are capable of doing their jobs safety.

Article 17. Appointment of the supervisor

1. The employer or the managing unit shall appoint an electrical safety supervisor when a work team, which is not specialized in electricity or not capable of electrical safety, works near energized items.

2. The managing unit shall appoint an electrical safety supervisor when the work team works at electrically dangerous places.

Article 18. Works under taken by multiple work teams

When a work is undertaken by multiple work teams of the same electricity agency, the employer shall appoint a general commander.

Article 19. Permission to work alone

The persons appointed to check the power line or equipment visually may do this alone. Always treat the lines and devices as energized when checking.

Article 20. Duties of the general commander

The general commander shall coordinate the operation of work teams during the work.

Article 21. Duties of the authorizer

1. The authorizer shall inspect the electrical safety engineering under their management to prepare the worksite for the work team.

2. Provide the work team with information about de-energized devices, energized parts, and special measures.

3. Sign permissions to work and handover the worksite to the work team.

Article 22. Duties of the electrical safety supervisor

1. Cooperate with the direct commander to receive the worksite.

2. Always be present at the worksite to supervise electrical safety for workers; do not undertake other tasks.

Section 2. DUTIES OF THE DIRECT COMMANDER

Article 23. Cooperation

The direct commander shall closely cooperate with the organizations concerned, direct and inspect the work team to ensure the safety.

Article 24. Inspection

1. The direct commander must grasp the works and safety measures suitable for such works.

2. The direct commander shall:

a) Inspect and take safety measures where necessary;

b) Comply with the regulations on safety applicable to workers;

c) Monitor the quality of protective equipment being used to work;

d) Install, move, and remove electrical safety signs, barriers, and portable grounding while working and form all workers.

Article 25. Provide cursory health checkups for workers

Before the carrying out a work, the direct commander shall provide cursory health checkups for workers. If a worker might not be able to do his tasks normally, he must not participate in the work.

Article 26. Explanation

Before the work team carries out the work, the direct commander shall provide the workers with explanation about the contents and order of the works and the safety measures.

Article 27. Supervision

The direct commander must be continuously present at the worksite, supervise and take measures for preventing workers from committing acts that might lead to accidents during the work.

Section 3. RESPONSIBILITY OF WORKERS

Article 28. Responsibility of workers

1. Grasp and comply with the safety regulations related to the work; recognize dangers, and proficient in giving first aid.

2. Comply with instructions of the direct commander and do not perform the tasks not being assigned by the direct commander. If the task assigned by the direct commander is impossible or is considered dangerous, the worker must immediately stop, report, and await orders from the direct commander.

3. If the order given by the direct commander cannot be followed, or the equipment, working conditions are considered unsafe, the worker is entitled to refuse to follow such order and inform a competent person.

Article 29. Restricted areas

Workers may not enter the areas that:

1. Are banned by the direct commander.

2. Are at risk of accidents.

Article 30. First aid

1. Each work team must have a first aid kit.

2. When an accident happens, all workers of the work team must give first aid to the victim and inform the nearest medical facility.

Chapter IV.

PROTECTIVE EQUIPMENT

Article 31. Requirements

1. All workers shall use protective equipment that suits their tasks. The direct commander shall inspect the use of protective equipment of their workers.

2. While working near a line with a voltage of 220kV or above which pose a risk of electrocution due to electrostatic induction, the workers must be provided with specialized protective equipment.

Article 32. Inspection of protective equipment

1. The protective equipment must meet the standards.

2. The protective equipment must be inspected and maintained in accordance with the instructions of the producers and current law. It is prohibited to use untested, expired, or unreliable protective equipment.

Article 33. Daily inspection

1. Before using protective equipment, the user must inspect them and only use them if they meet the requirements.

2. After being used, protective equipment must be cleaned, dried, and stored as regulations. Inform the manager about any unreliable protective equipment.

Article 34. Using equipment and tools while working live

The direct commander shall request workers to use tools and equipment for electrical repairs according to the work contents. It is prohibited to carry out electrical repairs without safety equipment and tools.

Article 35. Periodic inspection and maintenance of tools and equipment

1. Tools and equipment necessary for electrical repairs must be periodically inspected according to standards and be maintained as regulations.

2. It is prohibited to use unchecked, expired, or unreliable protective equipment for electrical repairs.

Article 36. Transporting protective equipment

Protective equipment must be packaged properly to avoid being damaged, deformed, dirty, oil, dirt, moisture, etc. during the transport.

Chapter V.

GENERAL SAFETY MEASURES

Section 1. PLAN

Article 37. Planning

The employer must make the working plan that suitable for the contents and order of the work with the cooperation with relevant departments (equipment management unit, operating unit, maintenance unit, etc.)

Article 38. Work registration

Before working with energized equipment where electrical safety measures must be taken, the work team shall apply for a registration with the managing unit.

Article 39. Cancellation or postponement of works due to bad weathers

1. Upon the occurrence of heavy rain, strong wind, lightning, or thick fog, outdoor works may be cancelled or delayed.

2. Upon the occurrence of rain condensation, outdoor works using insulating equipment are forbidden.

Section 2. WORK ORDERS AND WORK PERMITS

Article 40. Work permits

1. A work permit is a written permission to work with electrical equipment.

2. Each work team must obtain a work permit to do a separate work.

3. The direct commander shall only allow workers to work after the permission from the authorizer is obtained and necessary safety measures are taken.

Article 41. Work orders

A work order is a written or spoken order that is given directly or by phone. The order receivers must record it in the logbook. The logbook must specify: the order giver, the work location, commencement time, full names of the direct commander and workers. The work completion must be written in the logbook.

Article 42. The works that require work orders and work permits

Comply with the following regulations when working with electrical equipment and materials, near or related to energized equipment and materials:

1. Comply with the work order if the work does not require preparation for the worksite, is away from energized places, or when operators fixing equipment failure on their shift under the supervision of the shift workers (no work permit required).

2. Comply with the work permit when:

a) Working de-energized;

b) Working live;

c) Working near energized parts.

Article 43. Contents of a work permit

A work permit must contain the following information:

1. Full name of the permit issuer.

2. Full name of the general commander (if any).

3. Full name of the electrical safety supervisor (if any).

4. Full name of the authorizer.

5. Full name of the direct commander.

6. List of workers.

7. Work contents.

8. Working location.

9. Working time (time and date).

10. Working conditions (de-energized or live, near energized places).

11. Working range.

12. Safety measures taken at the working site.

13. Instructions or warnings given by the authorizers.

14. Other information (if any).

15. Work completion.

The template of the work permit is provided in the Appendix.

Section 3. SAFETY CONFIRMATION

Article 44. Confirm safety measures before working

Before the work is carried out, the direct commander must confirm that the safety measures at the worksite have been properly and adequately taken.

Article 45. Checking equipment

Before working, workers shall check safety equipment, protective equipment, tools, and machinery such as test pens

Section 4. SAFETY PRINCIPLES

Article 46. Working with loads

When lifting or lowering a load:

1. The worker must not stand or do anything within the dangerous zone of the lifting device.

2. The durability bearing cable must be suitable for the load.

3. The hook and pulleys must be locked to avoid dropping.

Article 47. Transporting heavy items

Take safety measures when transporting heavy items.

Article 48. Prevention of loss of working ability due to vibrating equipment

Take safety measures when working with vibrating such as chainsaws, rammers, etc.

Article 49. Checking before climbing up the platform

1. Before climbing up scaffolding, the worker must check:

a) The conditions of the platform or the pole;

b) The position of the platform and the climbing safety, structure and wires of the pole;

c) Safety equipment and protective equipment.

2. Take measures for preventing the pole from falling down when climbing unsound poles.

3. The direct commander shall stop the work if it threatens the safety of humans and equipment.

Article 50. Checking disconnection and leakage

When climbing up the electric pole, the worker must check de-energizing leakage by the test pens.

Article 51. Using climbing equipment

When working at a height or a depth at 1.5 meter from the ground, the worker must use appropriate climbing equipment.

Article 52. Fall prevention

When working at a height, the worker must use a safety harness. The safety harness must be firmly fixed.

Article 53. Preventing tools and materials from falling from a height

When using materials and tools from a height and when moving them up or down, the user must take measures for preventing them from falling down.

Article 54. Working with poles

1. Take measures to avoid tilting or dropping poles when installing and removing them.

2. Take measures to avoid accidents due to insufficient safety distance when installing and removing poles near power lines.

Article 55. Working with wires

Comply with the following requirements when installing or removing electrical wires:

1. Inspect the conditions of the supporting structure and cable, ensure the normal operation and take measures to prevent collapse of temporary cables, etc.

2. Take measures to ensure safety for the public such as putting warning signs, barriers, etc. and appoint watchmen where necessary.

Article 56. Working with electrical equipment

Take measures for avoiding dropping, collision, or accidents when lifting, lowering, or removing electrical equipment (transformers, circuit breakers, ceramic knobs, etc.) due to insufficient safety distance between the equipment and the electric wires or other electrical equipment.

Article 57. Digging

1. The work team shall take appropriate measures for preventing landslip.

2. The work team shall take measures to prevent people from falling into the holes such as setting up barriers, beacons, and appoint watchmen where necessary.

3. Before digging a hole, the work team must identify underground works below or near the worksite and take measures to avoid accidents or prevent them from being damaged. When discovering unexpected underground works or damaged underground works, the work team shall stop the work and inform a responsible person. When an underground work is damaged and causes accidents, the work team shall take appropriate measures for preventing further accidents and immediately inform the organizations concerned.

Section 5. WORK SUSPENSION

Article 58. Requirements during work suspension

When suspending a work, the safety measures that were taken such as grounding, barriers, and warning signs must be kept intact during the suspension. If no person stays at the site at night, the work team shall take appropriate measures to prevent accidents. Check and ensure all safety measures are the same as they were before the suspension when resuming the work.

Article 59. Handling unreliable equipment

1. When a device is found broken and might harm humans, the workers must immediately inform the responsible person after emergency measures have been taken to prevent it from harming humans.

2. When being informed about a broken device that might hurt humans, the employer must immediately take appropriate measures.

3. Cut off power when a risk of short-circuit or electrocution is present such as touching energized wires. Take appropriate measures if power cannot be cut off such as appointing watchmen to prevent accidents for humans.

Article 60. When an accident happens

When an accident happens, the direct commander and workers must immediately stop the work and:

1. Take appropriate measures to prevent other accidents and stay away from the broken device if danger is probable.

2. Give first aid to the victims and contact nearest medical facilities.

3. Inform the organizations concerned about the accident.

Article 61. First aid

Workers shall give first aid to the victims as follows:

1. Provide artificial respiration, stop the bleeding, etc.

2. Call an ambulance.

Article 62. Stopping and suspending works due to bad weather

The direct commander shall order the workers to stop or suspend the work if the weather turns bad.

Section 6. WORK COMPLETION

Article 63. Before handover

The direct commander shall follow the order below:

1. Directly inspect the completed works, gather tools, and clean the worksite.

2. Order the workers to leave the working positions, except for the people in charge of removing safety measures.

3. Order the removal of safety measures taken by the work team before the work is carried out.

4. Check to ensure the sufficient the number of people, tools, materials, and equipment.

5. Prevent workers from returning to the working site.

Article 64. Worksite handover

After the steps in Article 63 have been taken, the direct commander shall write and sign in the “work completion” box of the work permit and hand the worksite over to the authorizer.

Chapter VI.

SAFETY WHEN WORKING WITH ELECTRICAL EQUIPMENT

Article 65. Disconnect to work

1. When closing or cutting supplying power to the electrical equipment, the operator must be provided with appropriate protective equipment.

2. The disconnection must ensure that the equipment being work with, which is disconnected from all energized parts (except for GIS equipment), is seen after the disconnection.

Article 66. Working with generators and transformers

1. Cut all switchgears that are connected to the power line when working with deactivated devices such as generators, synchronous compensators, and transformers in order to prevent unexpected power supply.

2. Experiments with generators may be conducted when they are running without excitation. Experiments must be conducted in accordance with approved experiment processes.

Article 67. Flammable materials

1. If flammable materials such as oil, gas, hydrogen, acetylene, etc. are located at the site, the managing unit and the work team shall cooperate in taking appropriate fire and explosion prevention measures.

2. Avoid creating explosive hydrogen compounds when using hydrogen-cooled generators and synchronous compensators cooled by hydrogen. Such compounds are explosive when the hydrogen content in the atmosphere reaches 3.3% - 81.5%.

3. Avoid creating explosive compounds of hydrogen and oxygen when running electrolytic equipment. Such compounds are explosive when the hydrogen content and oxygen content in the atmosphere reaches 2.63% - 95%.

4. Take fire and explosion prevention measures such as ventilating the working site, separating the system from running systems when doing repairs in the seal oil system and ventilation system of hydrogen-cooled generators, synchronous compensators, electrolyzers that are deactivated.

5. Do not carry out hot works or works that emit sparks on the shell of the generator, compensator electrolyzer, or on the pipes of petroleum system that contain hydrogen.

6. The hot works such as welding may be carried out at least 15 m away from petroleum systems that contain hydrogen. Take special safety measures such as covering, checking for the existence of hydrogen in the air at the worksite, etc.

7. Hot works in a room where the electrolyzer is located may be carried out when it is deactivated, no hydrogen is found in the air, and the ventilation system operates continuously. When carrying out hot works with a running electrolyzer, all pipes that connect the running electrolyzer and the repairing equipment must be removed and capped. The worksite where hot works are carried out must be covered to prevent sparks from being emitted all over the place.

Article 68. Working with electric engines

1. Lock the transmission system that supply power to engines, lock the power supply of the engines, and put up warning signs to avoid accidental power supply when working with engines without disconnecting them from the electric circuit.

2. Short-circuit the three-phase circuit and ground three electrodes that supply power for the engine at the power supply if electrodes of an engine must be removed from the power supply when working with the engine.

3. The outlets and … must be covered and fixed with bolts. Those covers must be removed when the engine is running. The rotors of the engine such as the commutator, the flywheel, and the fan must be covered.

4. Take measures to prevent reverse rotation when working with pumps or fans.

Article 69. Working with switchgears

1. Take the following measures before working with switchgears that have automatic tripping mechanism and remote control:

a) Disconnect the power supply;

b) Close the valve that leads compressed air to the circuit breaker chamber or the run mechanism and release all gases;

c) Put up safety signs;

d) Lock the valve that leads compressed air to the cutter chamber or remove the valve handle when working inside the chamber.

2. The circuit, the circuit of the transmission system, and the signal circuit may be closed to test the switchgear without handover.

During the trial, the operator or the direct commander (if agreed by the operator) shall supply power to the control circuit, open the valve, and remove the signs.

If the work with the switchgear must be resumed after the trial, the operator or the direct commander (if agreed by the operator) shall take necessary technical measures for the work team to work.

3. Before working in a gas tank, the workers must:

a) Close all valves of the gas pipeline; lock the valve or remove the valve handle; put up a “no service” sign;

b) Release all gas from the tank and open the release valve.

4. Always control the circuit breaker with a remote control. Do not use the control panel at the circuit breaker. Only close the circuit breaker this way when preventing accidents or rescuing victims of electrical accidents.

5. Do not trip the circuit breaker if it does not trip after using the remote control, or all electrodes are not cut.

Article 70. Distance when digging

1. When digging, the equipment such as cars, excavators, etc. must work at least 1 meter away from the electric cable; the vibrating digging equipment must work at least 5.0 meters away from the cable.

2. Identify the location and depth of the cable under the supervision of the operator when digging above the electric cable. Do not use crowbars and shovels to dig at 0.4 m away from the cable.

Article 71. Cable reel

Fix the rough parts on before rolling the cable real on the road to prevent the reel from falling. Remove all nails from the reel and fix the cable leads.

Article 72. Peeling cables

Workers must be careful when removing the cover and insulator of the cable to avoid being hurt by the tools and hurting other people. Workers must be careful to avoid damaging other parts of the cable.

Article 73. Measuring transformers

When working with protective circuits, workers must avoid interfering with the grounding at the secondary parts of voltage transformers and current transformers. Secondary circuits of the current transformers must not be exposed.

Article 74. Working with battery systems

1. Prepare neutralizing substances suitable for the battery system.

2. Wear working clothes, protective glasses and rubber gloves when working with acid and alkali to prevent the body from being affected by acid and alkali.

3. Do not smoke in battery room. Put up a sign that says “Battery room – Inflammable – No Smoking” sign the battery room.

4. The battery room must be ventilated to prevent poisoning, fire, and explosion due to the gas released by the battery system.

Chapter VII.

NON-LIVE LINE WORKING

Article 75. Working order

When working at a de-energized place, the work team must comply with the following order:

1. Confirm that the worksite is de-energized.

2. Install portable grounding so that the whole work team is in the protected zone.

3. Ground every part of the de-energized device that might supply electricity to the worksite.

Article 76. Installation and removal of portable grounding

1. The work team shall install and remove portable grounding in accordance with the instructions of the direct commander.

2. When multiple work teams do relevant works, each team shall set up a separate portable grounding.

3. The removal of portable grounding to serve necessary works of the team shall be ordered by the direct commander. Grounding shall be set up again right after the work is finished.

4. When installing and removing portable grounding, workers must use insulating gloves and long sticks.

5. The grounding wire is made of copper or soft alloys and must be able to resist and electrodynamic and thermal effects.

6. The lead in contact with the ground shall be installed first; the lead connected to the conductor shall be installed later. This process shall be reversed when removing grounding.

Article 77. Permission to start working

The direct commander shall allow the work team to work after all safety measures are taken.

Article 78. Numbering equipment

The numbers of circuit breakers, disconnectors, cable leads, must be clearly indicated to avoid errors.

Article 79. Connecting and disconnecting equipment

1. Power lines and electrical equipment must be energized and de-energized with suitable circuit breakers.

2. Do not use disconnectors to energize and de-energize loaded current.

3. Confirm that the power line is unloaded when using a disconnector.

Article 80. Interlock circuits

After tripping the switchgears, the operator shall:

1. Lock the transmission, the control circuit, and the interlock circuit of the switchgear.

2. Put up safety signs.

3. Appoint watchmen where necessary.

Article 81. Releasing excess electric charge

1. The work team must release excess electric charge and install grounding before working.

2. Release excess electric charge during the operation and use protective equipment.

Article 82. Checking voltage

1. Confirm that the worksite is disconnected before working de-energized.

2. Check for leakage before working with a disconnected power line that shares the same pole with another energized power line.

3. Check for induced voltage with voltage testers if the disconnected circuit is located near or across a high-voltage circuit. Workers must inform the direct commander when induced voltage is detected. The direct commander shall provide appropriate solutions and instructions to ensure safety for the workers, such as grounding, and do not allow the work until appropriate measures and taken.

Article 83. Preventing reverse voltage

1. Portable grounding must be installed to prevent inverse voltage to the work site from the secondary coil of the transformer or other low-voltage power supplies.

2. Take appropriate measures for preventing inverse voltage from independent generators of clients when disconnecting a power line operating at a voltage up to 1000 V.

3. Remove the ground wires connected to the phase wires before remove the ground wire connected to the neutral wire.

Article 84. Handing over the worksite to the managing unit

The work team shall handover the site to the managing unit after the work is completed and grounding is removed by the work team.

Chapter VIII.

SAFETY ASSURANCE WHEN WORKING LIVE WIRES

Article 85. Working safety

1. Use appropriate protective equipment when working with energized power lines.

2. Check for leakage at metal components related to the energized power lines.

3. Workers must not wear jewelry or metal items when working with or near energized power lines.

4. When working live, the nearest energized parts must be visible at the position of workers.

Article 86. Conditions for working live

1. The list of energized devices while working and the list of live line works must be approved by competent persons.

2. The persons that do live-line works must be trained in using equipment, the process, and technologies with which they are provided.

Article 87. Measures for works with a voltage below 1,000 V

1. If the risk of electrocution is posing, the employer must request workers to:

a) Use appropriate protective equipment.

b) Cover the charged components of the electrical equipment by protective equipment to eliminate the risk.

2. Workers must use protective clothing and protective equipment at the request of the employer.

Article 88. Measures for works with a voltage above 1,000 V

1. If workers are at risk of electrocution when working with circuits with a voltage of 1,000 V or above such as checking, repairing, cleaning energized parts or ceramic insulators, the employer must request workers to use equipment and tools for working live. In this case, the minimum permissible distance to the worker must be conformable with the table below:

Voltage (kV) | Minimum permissible distance (m) |

Up to 35 | 0.6 |

Above 35 to 100 | 1.0 |

220 | 2.0 |

500 | 4.0 |

2. Workers must not do live line works alone. In an emergency, workers must inform the responsible person and await orders from the direct commander.

3. Ensure the distance to the wire according to Clause 1 of this Article when taking metal tools or components up the pole.

Article 89. Using covers

On the power lines that have a voltage up to 35 kV, when the distance between the wire and the center of the wooden pole or the surface of the steel pole is shorter than 1.5 m and bigger than 1 m, works may be carried out on the pole with insulating covers to prevent humans from touching the wire or the ceramic insulators.

Article 90. Strengthening before working live

Repairs of energized power lines shall only be carried out if the lines and the poles are completely reliable. If the pole parts are not reliable, the pole must be strengthened before replacing them.

Article 91. Replacement of ceramic insulators

When replacing ceramic insulators on the power lines operating at a voltage of 110 kV or above, only the first and the second insulators from the crossbar may be touched. Only touch the first insulator on a 35-kV power line if there are two insulators. The first and the second insulator may be touched if there are three or four insulators.

Article 92. Insulation cleaning

The insulation cleaning must be carried out by at least two people using appropriate tools and protective equipment.

Article 93. Bare-hand working

1. Do not touch the ceramic insulators or other parts that are charged to the same voltage as the line when standing on insulating equipment that has a voltage equal to that of the wire. Wear insulating gloves when installing and removing the parts with various voltages of the phase being repaired.

2. Do not give or take anything when working on insulating equipment that is charged to the same voltage as the line.

3. Do not move on insulating equipment after the worker is charge to the same voltage as the line. Only enter and leave the working zone of the insulating equipment after the distance between the worker and the wire reaches at least the minimum distance in the table below, and after the voltages of the worker and the wire are no longer equal

Voltage (kV) | Minimum distance (m) |

Up to 110 | 0.5 |

220 | 1.0 |

500 | 2.5 |

Chapter IX.

SAFETY ASSURANCE WHEN WORKING NEAR ENERGIZED WIRES

Article 94. Working near power lines that have a voltage 1,000 V or above

1. Workers must be provided with and use appropriate protective equipment.

2. Workers must keep a safety distance from energized power lines. The safety distances at various voltages are provided below:

Voltage (kV) | Minimum permissible distance (m) |

Up to 35 | 0.6 |

Above 35 to 66 | 0.8 |

Above 66 to 110 | 1.0 |

Above 110 to 220 | 2.0 |

Above 220 to 500 | 4.0 |

3. If the minimum permissible distance according to Clause 2 of this Article cannot be ensured, the employer may not allow workers to work near energized power lines. In such cases, power supply must cut before working.

Article 94. Working near power lines operating a voltage of below 1,000 V

1. If workers are at risk of electrocution at a close distance with the power line that has a voltage of below 1,000 V, the direct commander shall request workers to cover the live energized parts of the equipment by protective equipment to avoid risk of danger.

2. Workers must use protective clothing and protective equipment when covering the energized parts.

Article 96. Replacing and stretching wires

1. When carrying out the works that might drop or loosen wires (such as disconnecting or connecting wires at the beginning of the ceramic chain) at the intersection of the pole an other power lines that have a voltage of above 1,000 V, those wires may be keep energized if the wire that needs repairing is below the energized power lines.

2. When replacing a wire at the intersection, the work team must take measures for preventing the wire that needs replacing from being thrown to the energized power lines above.

Article 97. Working with lighting wires

When working lightning wire on the rod that is located within the affected area of energized power lines, the lightning wire must be connected to the steel pole, or the grounding wire of the concrete pole or wooden pole, to eliminate induced voltage. To prevent induced voltage that might harm workers when working with wires, the work team must connect the wire with the crossarm of the steel pole or the grounding wire of the wooden pole or concrete pole at the worksite.

Article 98. Using steel cables

1. The minimum permissible distance between the steel cable and the guy wires to the energized power lines are provided below:

Voltage (kV) | Minimum permissible distance (m) |

Up to 35 | 2.5 |

Above 35 to 110 | 3.0 |

Above 110 to 220 | 4.0 |

Above 220 to 500 | 6.0 |

2. If the guy wire may be moved close to the energized wires at a shorter distance than the distances specified in Clause 1 of this Article, such guy wires must be keep at a sufficient distance from the energized wires. The steel cable must be arranged so that it would not be thrown to the energized wires if it were broken.

Article 99. Working on a disconnected power line that share the same pole with energized power lines

1. Only climb up a pole, on which one circuit is disconnected and the other circuit is still energized, when the distance between two nearest wires of two circuits is not shorter than the distance provided in the table below:

Voltage (kV) | Minimum distance (m) |

Up to 35 | 3.0 |

66 | 3.5 |

110 | 4.0 |

220 | 6.0 |

2. For 35-kV power lines where the distance between two closet wires of two circuits is shorter than 3.0 m but not shorter than 2.0 m, the works on a pole, on which one circuit is disconnected and the other is still energized, may be carried out as long as an insulating partition is placed between two circuits.

3. Do not work with 2-circuit wires of which one circuit is still energized in strong wind that might shake the belt and the cable and cause difficulties for workers on the pole.

Chapter X.

MEASURES FOR WORKING AT DANGEROUS POSITIONS DUE TO LACK OF OXYGEN

Article 100. Preparation before work

1. Set up barriers

Appropriate measures such as setting up barriers must be taken to prevent unauthorized people from entering the worksite. Danger signs must be place at noticeable places.

2. Rescue equipment

The work team must have rescue equipment such as respirators. Workers must put rescue equipment at convenient places to use in an emergency. The number of respirators must be larger than the number of members of the work team.

3. Measuring of concentrations of oxygen and toxic gases.

a) Workers must measure the concentrations of oxygen and toxic gas to ensure that such concentrations meet the standards provided in the table below. The measurement results must be recorded;

Gas | Safe concentration |

Oxygen | ≥ 18% |

Carbon monoxide | ≤ 0.005% (50ppm) |

Flammable gas | < 30% below flash point |

Hydrogen sulfide | ≤ 10ppm |

b) If the concentration of flammable gas does not meet the standard in Point a of this Clause, the direct commander shall order all workers to leave the worksite and go to a safe place. Do not use flame or flammable products, and immediately take appropriate measures such as ventilation.

c) If the concentrations of oxygen and hydrogen sulfide does not meet the standards in Point a of this Clause, workers must ventilate the worksite to increase the oxygen concentration up to 18% and decrease the concentration of hydrogen sulfide to 10ppm or below.

4. Do not use pure oxygen to ventilate.

Article 101. Measures taken during work

1. Ventilation

The worksite must be sufficiently and continuously ventilated to keep the concentration of oxygen stable through out the work.

2. Using flammable products

The use of fire and flammable products must be prohibited, unless it is necessary. When the use of fire and flammable products is necessary, workers must do it on the ground as much as possible.

3. Appointment of watchmen

Direct commander shall appoint watchmen throughout the work to communicate with workers working inside holes or tunnels.

Article 102. Measures taken when accidents happen

1. Evacuation

Workers must immediately inform the direct commander when realizing risks of accidents such as fire, explosion, or lack of oxygen at the worksite. The direct commander shall assess the situation and order workers to stop working, leave the worksite and go to a safe place if necessary. The work team must take necessary measures to minimize risk of accidents.

2. Medical examination and treatment

The employer must consider the health of the workers that are affected by the lack of oxygen or poisoned by toxic gas to provide medical examination and treatment.

Chapter XI.

SPECIALIZED VEHICLES

Article 103. Operation

1. Only trained and qualified people are allowed to operate specialized vehicles.

2. The operator must check specialized vehicles before running.

Article 104. Speed

The speed of vehicles must not exceed 5 km/h when moving within an electric station area.

Article 105. Minimum distance

When moving in a station area, the shortest distance from any part of the vehicle to the energized parts of the station must not fall below the distances provided in the table below:

Voltage (kV) | Distance (m) |

Up to 35 | 1.0 |

Above 35 to 110 | 1.5 |

220 | 2.5 |

500 | 4.5 |

Article 106. Grounding

When carrying out partially de-energized works or working live near energized parts, the platform of the crane truck, ladder truck, or bucket truck must be grounded.

Article 107. Vehicle problems

1. When there are electric arcs between the vehicle and the energized parts, do not touch the vehicle nor leave the vehicle nor get on the vehicle before the source of electric arc is disconnected.

2. Jump out of the vehicle if it burns and power supply is not disconnected. Jump with both legs and stand still; jump with both legs to get away from the vehicle where necessary.

Article 108. Periodic inspection

Specialized vehicles must be inspected periodically.

Article 109. Forbidding operation

Do not operate crane trucks, ladder trucks, bucket trucks, etc. in strong wind.

Article 110. Operation plan

1. When using a specialized vehicle, the employer must make an operating process that suit the space and area of the worksite, the category and capacity of the vehicle, the type and shape of the load, and ensure sufficient operators according to plan.

2. The operation plan must describe the itinerary and operation method of relevant specialized vehicles.

3. The employer must propagate the operation plan among the workers concerned.

Article 111. Fall prevention

1. When a worker is operating a specialized vehicle, the direct commander shall take safety measures such as ensuring sufficient width, leveling the ground, take measures for preventing the road from being damaged, etc. to minimize dangers to workers such as vehicle falling, etc.

2. When operating the vehicle on the roadside or on a sloping terrain, etc. the direct commander shall appoint guides to instruct the vehicle if workers are facing dangers such as vehicle falling.

3. The vehicle operator must comply with the instructions of the guide.

Article 112. Collision prevention

When working with specialized vehicles, the direct commander must not allow workers to enter the dangerous zones of such vehicles.

Article 113. Crane

The operation, maintenance, repair and inspection of cranes must comply with current regulations on lifting equipment.

Article 114. Safety harness

When working at a height with a specialized vehicle, the direct commander shall command workers to stand at correct positions and wear safety harnesses.

Chapter XII.

TESTING STATIONS AND LABORATORY

Article 115. Barriers, safety distance, and grounding

1. The places having a voltage of 1,000 V or above in the testing station or laboratory must be separated with barriers.

2. The distance from the inductors of the conductor of the tested equipment to the grounded fixed barrier must not be shorter than the distance provided below:

a) For pulse voltage (amplitude values)

Voltage (kV) | Distance (m) |

Up to 100 | 0.5 |

Above 100 to 150 | 0.75 |

Above 150 to 400 | 1.0 |

Above 400 to 500 | 1.5 |

Above 500 to 1000 | 2.5 |

Above 1000 to 1500 | 4.0 |

Above 1500 to 2000 | 5.0 |

Above 2000 to 2500 | 6.0 |

b) For industrial frequency voltage, effective voltage and direct current:

Voltage (kV) | Distance (m) |

Up to 6 | 0.1 |

Above 6 to 10 | 0.2 |

Above 10 to 20 | 0.3 |

Above 20 to 50 | 0.5 |

Above 50 to 100 | 1.0 |

Above 100 to 250 | 1.5 |

Above 250 to 400 | 2.5 |

Above 400 to 800 | 4.0 |

The distance to the temporary barriers must be three times as longer as the distances above.

3. The height of fixed barriers must not be shorter than 1.7 meters; the height of temporary barriers must not be shorter than 1.2 meters. The barrier structure must ensure that not people accidentally touched energized parts

4. The doors of barriers must be opened outwards or to the sides. The doors must be locked by automatic locks and can be unlocked from the inside without keys.

5. The barriers of testing locations within a testing station do not have to be locked if unauthorized people cannot access these places.

6. Fixed barriers can only be disassembled with keys or special tools. Do not enter to cheek transformers until their covers are grounded and the distance from the lowest ceramic insulators are not shorter than the values below:

Voltage (kV) | Distance (m) |

Up to 10 | 1.5 |

Above 10 to 35 | 2.0 |

Above 35 to 110 | 2.5 |

7. The transformers used for testing insulation must be connected to circuit breakers that automatically trip when insulation fails in order to minimize short-circuit.

8. The capacitors and power inverters used in the testing diagram that are put outside the testing areas must be barricaded.

9. The frames, shells, bodies of test subjects and testing equipment, testing tables, portable power tools, metal barriers, and measurement devices in metal shells must be grounded. If the shell of a device cannot be grounded for some reason, it must be barricaded.

10. In the diagram of function generators and cascade DC generators, a device that automatically grounds all capacitor must be inserted when rectifiers are disconnected.

11. The equipment with high electricity capacitance that are not participated in the testing but located in the testing areas must be short-circuited and grounded.

When testing equipment with high electricity capacitance, such as capacitors and cables, the testing areas must have equipment for short-circuiting and connecting the test subjects to the ground.

When the testing is finished, the capacitors tested must be discharged and grounded. The capacitors connected continuously must be discharged. Capacitors must be discharged until no more sparks are seen.

Article 116. Periodic inspection of testing equipment and devices

The managing unit of the testing station or laboratory must periodically check the testing equipment and devices. The defective equipment and devices must not be used.

Article 117. Confirming testing circuits

1. Before starting the testing, the circuit that connects tested devices must be checked to confirm the accuracy of the testing diagram.

2. Only install and remove test subjects when the direct commander permits.

3. The testing diagram must be checked to prevent reverse voltage through the transformer before the connection.

Article 118. Arcing testing

Before doing arcing tests or other risky tests, workers must:

1. Assure that no people are in the dangerous area.

2. Assure that no unauthorized people are in the worksite.

3. Put up warning signs and barricade to prevent unauthorized people from entering the testing area.

Article 119. Capacitors

1. The circuit that supplies the capacitors must have a circuit breaker located at the secondary circuit of the tested transformer.

2. Only install and remove test subjects when the direct commander permits and after the power supply to connecting capacitors is cut off.

Article 120. Testing mechanical strength of insulators

Do not stand near the testing area when testing the mechanical strength of insulators (ceramic, glass, synthetic plastic, etc). Take measures for eliminating risk of accidents to workers caused by flying fragments.

Article 121. Prevention of testing voltage

1. To prevent testing voltage from affecting the working voltage, the distance between two energized parts must comply with the table below:

Normal voltage of the device (kV) | Up to | |||

10 | 15 | 20 | 35 | |

Minimum distance (cm) | 15 | 20 | 25 | 50 |

2. Comply with the conditions below when mobile or and fixed testing stations:

a) The testing device shall be divided into two parts: one part is where the devices operating at a voltage below 1,000 V is placed and the operator is positioned; the other part is where all devices and wires operating at a voltage of 1,000 V or above are placed;

b) The devices operating at a voltage of 1,000 V and above must be carefully barricaded to prevent people from getting close to them;

c) Doors of the devices that have a voltage above 1,000 V must have electric interlocks so that the voltage above 1,000 V is cut when the door is opened and a light is turned on when this part is energized;

d) The arrangement of all devices operating at a voltage below 1,000 V must facilitate the operation and inspection.

Chapter XIII.

IMPLEMENTATION

Article 122. Responsibility for the implementation

1. Electricity users and participants in electrical activities shall provide instructions to ensure safety during such activities and electricity. Those instructions must not contradict this Regulation and other laws.

2. Services of Industry and Trade of provinces and cities shall provide instructions and inspect the adherence to this Regulation of local electricity users and participants in electrical activities.

3. The Industrial Safety Techniques and Environment Agency – the Ministry of Industry and Trade shall provide instructions and inspect the adherence to this Regulation of Services of Industry and Trade, electricity users and participants in electrical activities nationwide.

4. Electricity users and participants in electricity activities shall send periodic reports on electrical safety engineering to Services of Industry and Trade, Services of Industry and Trade shall send summary reports to the Ministry of Industry and Trade before the 15th of June and December. The reports shall focus on the inspection of protective equipment, electrical accidents and other unusual events.

Article 123. Settling difficulties during the implementation

Difficulties that arise during the implementation should be reported to the Ministry of Industry and Trade for consideration and settlement./.

APPENDIX

WORK PERMIT

ISSUER …………………..... | WORK PERMIT | No. .......... |

1. Recipient:

1.1. General Commander (if any):

1.2. Direct commander:

1.3. Workers: (quantity)

1.4. Work location:.............................................(1)..........................................

1.5. Work contents:.............................................(2)..........................................

…………..................................................................................................................

1.6. Schedule:

- Begin at (time and date):

- Finish at (time and date):

1.7. Working conditions (partially or completely disconnected devices, power lines):

Date of issue:

Issuer:

Full name ………………………………… Position: ……………….............................

Signature: .................................................................................................................

2. Procedure

2.1. Disconnected devices, wires, and wire segments: …….…(3)…………

2.2. Grounding positions: ………………………………………(4)…………………

2.3. Positions of barricades and warning signs: ………………………(5)……………

2.4. Working range: …………………….…………(6)…………………

2.5. Warnings and instructions: …………………………………(7)…………………

2.6. Commencement time (time and date):

Authorizer:

Full name ………………………………… Position: ……………….............................

Signature: ................................................................................................................

3. Worksite handover

3.1. Inspected on-site safety measures: …………………………

3.2. Additional safety measures and grounding positions: ………………(9)………

Commencement time (time and date):

General Commander (if any):

Full name ………………………………… Position: ………………...........................

Signature: ..............................................................................................................

1.2. Direct commander (signature and full name)

Full name ………………………………… Position: ………………..........................

Signature: ...............................................................................................................

Electrical safety supervisor (signature and full name – if any):

Full name ………………………………… Position: ………………...........................

Signature: ..............................................................................................................

4. List of workers (and replacements – if any)

No. | Full name | Time and date | Signature | |

Arrival | Departure | |||

1 |

|

|

|

|

2 |

|

|

|

|

3 |

|

|

|

|

4 |

|

|

|

|

5. Permission to work, to finish daily work, and to change working location:

No. | Working location | Time and date | Direct commander (signature or name) | Authorizer (signature or name) | |

Begin | Complete | ||||

1 |

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

6. Work completion:

6.1. All works are completed, tools are gathered, people, grounding, and safety measures are removed to ensure connection safety. The direct commander has handed over the worksite to Mr./Mrs. ………………………………………., Position: ……………………… at ………………………………………….

Signature of the direct commander:

Signature of the General Commander (if any):

6.2. The worksite is handed over and the work permit is closed at (time and date):

Authorizer (signature or name):

Finish at (time and date):

Issuer (signature or name):

Notes: Depending on the production organization and actual conditions, the participant in electricity activities and electricity users shall provide instructions on the work permit. Those instructions must not contradict this form.

------------------------------------------------------------------------------------------------------

This translation is made by LawSoft and for reference purposes only. Its copyright is owned by LawSoft and protected under Clause 2, Article 14 of the Law on Intellectual Property.Your comments are always welcomed