Nội dung toàn văn Circular 03/2020/TT-BYT amendments Circular 11/2018/TT-BYT quality of pharmaceutical products

|

THE MINISTRY OF HEALTH |

THE SOCIALIST REPUBLIC OF VIETNAM |

|

No. 03/2020/TT-BYT |

Hanoi, January 22, 2020 |

CIRCULAR

AMENDMENTS TO SOME ARTICLES OF THE CIRCULAR NO. 11/2018/TT-BYT DATED MAY 04, 2018 OF THE MINISTRY OF HEALTH OF QUALITY OF PHARMACEUTICAL PRODUCTS AND PHARMACEUTICAL STARTING MATERIALS

Pursuant to the Law on Pharmacy No. 105/2016/QH13 dated April 06, 2016;

Pursuant to the Government’s Decree No. 54/2017/ND-CP dated May 08, 2017 on guidelines for the implementation of the Law on Pharmacy;

Pursuant to the Government’s Decree No. 155/2018/ND-CP dated May 08, 2017 on amendments to some Articles related to business conditions under state management of the Ministry of Health;

Pursuant to the Government’s Decree No. 75/2017/ND-CP dated June 20, 2017 defining functions, tasks, powers and organizational structure of the Ministry of Health;

At the request of the Director General of the Drug Administration of Vietnam,

The Ministry of Health hereby promulgates a Circular on amendments to some Articles of the Circular No. 11/2018/TT-BYT dated May 04, 2018 of the Minister of Health on quality of pharmaceutical products and pharmaceutical starting materials.

Article 1. Amendments to some Articles of the Circular No. 11/2018/TT-BYT dated May 04, 2018 of the Minister of Health on quality of pharmaceutical products and pharmaceutical starting materials

1. Article 1 is amended as follows:

“This Circular provides for application of quality standards for pharmaceutical products (modern pharmaceutical products, herbal materials, vaccines and biologicals) and pharmaceutical starting materials (including semi-finished and finished ones, excluding herbal materials); pharmaceutical product and pharmaceutical starting material tests and procedures for recall and handling of violating pharmaceutical products.”

2. Clause 1 of Article 7 is amended as follows:

“1. Apply quality standards to pharmaceutical product and pharmaceutical starting material tests:

a) The test must be carried out in accordance with the approved and updated pharmaceutical product/pharmaceutical starting material quality standards.

If the pharmaceutical product/pharmaceutical starting material quality standard is yet to be updated, the testing facility shall use the equivalent pharmacopeia specified in Clauses 1 and 2 Article 6 of this Circular, based on the production date of the pharmaceutical product/pharmaceutical starting material quality standard is yet to be updated being tested.

If the pharmaceutical product is prepared in a health facility, the test is carried out in accordance with the pharmaceutical product quality standards formed and promulgated by the facility.

b) If a testing method specified in the pharmaceutical product/pharmaceutical starting material quality standard contains errors, thereby failing to ensure the accuracy or trueness or a qualitative test is non-specific or an herbal material to which the addition of an active ingredient/chemical substance is suspected (the pharmaceutical product has side effects or unreported side effects, or foreign pharmaceutical regulatory agencies inform that the pharmaceutical product/pharmaceutical starting material contains impurities, the state-owned pharmaceutical product testing facility is entitled to apply the analytical/testing methods specified in the pharmacopoeia or validated according to the guidelines on analytical method validation enclosed with the Circular No. 32/2018/TT-BYT dated November 12, 2018 of the Minister of Health. The head of the pharmaceutical product testing facility shall be responsible to the law for its testing results.”

3. Point c Clause 3 of Article 7 is amended as follows:

“c) The testing facility must present the test/analysis results of the pharmaceutical product sample within 20 days after receiving it in the following cases:

- The pharmaceutical product requires testing before circulation as specified in Clause 1 Article 8 of this Circular, except for the vaccine or biological that is serum containing antibodies and derivatives of human blood and plasma as specified in Clause 2 Article 10 of this Circular.

- The pharmaceutical product does not fit any of the cases mentioned in Points b and d of this Clause.”

4. Clause 6 of Article 7 is amended as follows:

“6. Archiving records and documents:

a) The records and documents on pharmaceutical product/pharmaceutical starting material quality inspection must be archived as specified in the Law on Archives, Decrees elaborating the Law on Archives and Circular No. 53/2017/TT-BYT dated December 29, 2017 of the Minister of Health.

b) After the end of their archiving periods, the records and documents shall be handled in accordance with regulations of the Law on Archives.”

5. Clause 3 of Article 8 is amended as follows:

“3. The Ministry of Health (Drug Administration of Vietnam) shall designate GLP-compliant testing facilities to carry out pharmaceutical product tests specified in Clause 1 of this Article, including:

a) GLP-compliant testing facilities specified in Article 1 Article 35 of the Law on Pharmacy, including state-owned ones;

b) Pharmaceutical product/pharmaceutical starting material testing service providers granted the Certificate of eligibility for pharmacy business that allows pharmaceutical product testing;

c) GLP-compliant testing facilities affiliated to SRA - Stringent Regulatory Authorities or designated by these authorities to carry out pharmaceutical product/pharmaceutical starting material tests to serve pharmaceutical product quality management;

d) National public testing facilities that prequalified and published by WHO according to the pharmaceutical product testing laboratory prequalification program.

If the testing facility does not have sufficient capacity for carrying out one or multiple tests, the testing facility must notify the producer/importer and cooperate with the latter in sending samples to other GLP-compliant testing facilities or ISO/IEC 17025 compliant laboratories which have capacity for carrying out those tests.”

6. Point d is added to Clause 6 of Article 8 as follows:

“d) Select a testing facility that satisfies the regulation laid down in Point a Clause 3 of this Article so that samples are sent to such testing facility. If the testing facility does not have sufficient capacity for testing one or multiple quality criteria, the testing facility must cooperate with the testing facility in sending sealed samples to the testing facility that has capacity for testing those criteria.”

7. Title of Clause 2 of Article 10 is amended as follows:

“Within 60 days from the date on which all samples and documents specified in Article 11 of this Circular are received, the National Institute for Control of Vaccines and Biologicals shall:”

8. Point c Clause 1 of Article 11 is amended as follows:

“b) The vaccine/biological samples to be tested on (the number of samples for each kind of vaccine/biological is specified in the Guidelines of the Ministry of Health for lot release testing of vaccines and biologicals which are seria containing antibodies and derivatives of human blood and plasma);”

9. Point b Clause 2 of Article 11 is amended as follows:

“b) The vaccine/biological samples to be tested on (the number of samples for each kind of vaccine/biological is specified in the Guidelines of the Ministry of Health for lot release testing of vaccines and biologicals which are seria containing antibodies and derivatives of human blood and plasma);”

10. Clause 4 is added to Article 11 as follows:

“4. The lot summary protocols shall be made according to WHO guidelines provided in the Form No. 09 in the Appendix II hereof.”

11. Article 14 is amended as follows:

“Article 14. Handling of pharmaceutical products not meeting quality standards by place of collection

1. In the case of violating pharmaceutical product samples collected by quality inspection authorities from retailers, level-III and level-IV health facilities (hereinafter referred to as “retailers”):

a) Within 24 hours from the time the testing facility’s test/analysis report is received, the Department of Health shall seal the substandard pharmaceutical products at the facility where the samples were collected from;

b) Within 48 hours from the time the testing facility’s test/analysis report is received, the Ministry of Health (Drug Administration of Vietnam) request shall request the responsible pharmaceutical product registrant/producer/importer in writing to cooperate with the distributor in:

- reporting its pharmaceutical distribution to wholesalers, health facilities at level II or higher (number of pharmaceutical products manufactured and imported; name and address of the pharmaceutical product purchasers, number of pharmaceutical products purchased and number of pharmaceutical products in stock) to the Ministry of Health (Drug Administration of Vietnam) and Department of Health within 07 days from the date on which the written request is made;

- requesting and cooperating with quality inspection authorities to collect additional samples from domestic pharmaceutical product manufacturers or importers, and from at least 02 pharmaceutical product trading establishments as prescribed in Clause 4 of this Article; sending a report thereon to the Ministry of Health (Drug Administration of Vietnam) within 15 days from the date on which the written request is made;

- sending samples to central testing facilities in order to have the unfulfilled criteria tested.

c) According to the result of testing of additional samples, the Drug Administration of Vietnam shall follow the instructions provided in Clause 5 of this Article.

2. In the case of violating pharmaceutical product samples collected by quality inspection authorities from wholesalers, level-II or above health facilities (hereinafter referred to as “wholesalers”):

a) Within 24 hours from the time the testing facility’s test/analysis report is received, the Department of Health shall seal the substandard pharmaceutical products at the facility where the samples were collected from;

b) Within 48 hours from the time the testing facility’s test/analysis report is received, the Ministry of Health (Drug Administration of Vietnam) shall identify the violation’s seriousness and draw the conclusion on recalling the violating pharmaceutical product as specified in Appendix II issued together with this Circular, and shall:

- issue the pharmaceutical product recall decision within the province or central-affiliated city where the samples were collected from and the pharmaceutical product trading establishments provided with pharmaceutical products by wholesalers from which samples were collected as specified in Clauses 3 and 4 Article 12 of this Circular;

- request the responsible registrant, producer or importer in writing to cooperate with the distributor in:

+ reporting its pharmaceutical distribution to wholesalers (number of pharmaceutical products imported; name and address of the pharmaceutical product purchasers, number of pharmaceutical products purchased and number of pharmaceutical products in stock) to the Ministry of Health (Drug Administration of Vietnam) within 07 days from the written request is made;

+ requesting and cooperating with quality inspection authorities to collect additional samples from domestic pharmaceutical product manufacturers or importers as prescribed in Clause 4 of this Article; sending a report thereon to the Ministry of Health (Drug Administration of Vietnam) within 15 days from the date on which the written request is made;

+ sending samples to central testing facilities in order to have the unfulfilled criteria tested.

c) According to the result of testing of additional samples, the Drug Administration of Vietnam shall follow the instructions provided in Clause 5 of this Article.

3. If the sample was collected by a quality inspection authority from manufacturers, importers and preservation service providers, or the sample's quality violation is identified to be caused by the production process, or samples of the same pharmaceutical product batch are collected from 02 wholesalers, the Ministry of Health (Drug Administration of Vietnam) shall identify the violation’s seriousness and draw the conclusion on recalling the violating pharmaceutical product as specified in Appendix II issued together with this Circular, and issue the pharmaceutical product recall decision as specified in Clause 3, Article 12 of this Circular. The recall's scope and time limit are specified in Clause 3 Article 63 of the Law on Pharmacy.

4. Requirements for collecting additional samples for quality testing as prescribed in Clauses 1 and 2 of this Article:

The pharmaceutical product quality inspection authority shall determine a sampling method according to the report on distribution by manufacturers and importers; pharmaceutical product samples shall be collected from wholesalers and retailers in the following order of priority a, b, c, d and dd:

a) From wholesalers within different provinces and cities, including the wholesalers that provided pharmaceutical products to the facilities from which samples were collected;

b) From wholesalers within different provinces and cities;

c) From wholesalers within the same provinces and cities;

d) From wholesalers and retailers;

dd) From retailers.

e) Samples shall be only collected adopting the method dd if manufacturers and importers prove that pharmaceutical products are no longer stored at wholesalers. Additional samples of recalled pharmaceutical products shall not be collected.

5. Handling of results of testing of additional samples.

a) If the additional samples meet quality standard, Ministry of Health (Drug Administration of Vietnam) shall issue a document identifying the violation’s seriousness and facility responsible for the violation and direct provincial Departments of Health to handle pharmaceutical products of the first retailers from which samples were collected in the case specified in Clause 1 of this Article or wholesalers and recalled pharmaceutical products within provinces and cities in the case specified in Clause 2 of this Article.

The recall's scope and time limit are specified in Clause 3 Article 63 of the Law on Pharmacy;

b) If at least 01 (one) additional sample collected at retailers fails to meet the quality standards, except for the case specified in Point a of this Clause, the Ministry of Health (Drug Administration) shall identify the violation’s seriousness and facility responsible for the violation, direct the provincial Department of Health to handle pharmaceutical products at retailers from which the samples were collected and issue a warning about the pharmaceutical product storage conditions and quality.

c) If at least 01 (one) additional sample collected at wholesalers or all additional samples are collected at retailers as prescribed in Point dd Clause 4 of this Article fail to meet the quality standards, the Ministry of Health (Drug Administration) shall identify the violation’s seriousness and draw the conclusion on recalling the violating pharmaceutical product as specified in Appendix II issued together with this Circular, and issue the pharmaceutical product recall decision as specified in Clause 3 Article 12 of this Circular.”

12. Point d is added to Clause 2 of Article 15 as follows:

“d) The pharmaceutical product is counterfeit, illegally imported, of unknown origins, expired, composed of banned substances, produced from raw materials that fail to meet quality standards or required to be recalled as prescribed in the Decree on administrative penalties for violations against regulations on health or its stored samples are unexpired.

13. Clause 6 of Article 15 is amended as follows:

“6. Pharmaceutical product destruction:

a) The head of the facility that has pharmaceutical products to be destroyed shall decide to form the pharmaceutical product destruction council responsible for organizing the destruction, deciding destruction methods and supervising the destruction. The council shall have at least 03 persons, with one representative having professional responsibility;

b) Pharmaceutical product destruction must be safe for both humans and animals, does not pollute the environment in accordance with regulations of law on environmental protection.

The facility that has pharmaceutical products to be destroyed shall take total responsibility for the destruction and submit a pharmaceutical product destruction report enclosed with a destruction record to the local Department of Health in accordance with the Form No. 06 in the Appendix III hereof.

c) Vaccine destruction:

- 07 days before the vaccine destruction, the facility destroying vaccines must send a destruction plan to the local Department of Health, including information about the name, number, concentration or content of each vaccine to be destroyed, reasons for destruction, date and place of destruction and destruction method. The Department of Health shall supervise the vaccine destruction.

- Vaccine destruction procedures and vaccine destruction shall comply with regulations of the Joint Circular No. 58/2015/TTLT-BYT-BTNMT dated December 31 of the Minister of Health and Minister of Natural Resources and Environment and Circular No. 36/2015/TT-BTNMT dated June 30, 2015 of the Minister of Natural Resources and Environment.

- Within 07 days from the end of the vaccine destruction, the facility shall submit a vaccine destruction report enclosed with a destruction record to the local Department of Health and Drug Administration of Vietnam.

The destruction record shall be made using the Form No. 06 in the Appendix III hereof.

d) The destruction of controlled pharmaceutical products shall comply with Article 48 of the Decree No. 54/2017/ND-CP .”

14. Point b Clause 1 of Article 18 is amended and Point e is added thereto as follows:

“b) Take charge and cooperate with the National Institute of Drug Quality Control, the Institute of Drug Quality Control of Ho Chi Minh City, the National Institute for Control of Vaccines and Biologicals in formulating plans to collect pharmaceutical product samples for quality inspections carried out at facilities in charge of production, preparation, import, export, storage, wholesaling, retail and use of pharmaceutical products nationwide, and present those plans to the Ministry of Health for consideration and approval, and allocation of budget for plan implementation within the Ministry’s competence.

Collect pharmaceutical product samples for quality inspection according to the approved plans and update the Ministry of Health’s pharmaceutical quality inspection database with information on collected pharmaceutical products/pharmaceutical starting material samples (including names of pharmaceutical products/pharmaceutical starting materials, concentration, content, dosage form, batch number, expiry date, number of certificate of registration or import license, manufacturer, importer, sample collector) and the pharmaceutical product/pharmaceutical starting material quality inspection results;”

“e) Take charge and cooperate with relevant competent authorities in translating, publishing and updating WHO guidelines for pharmaceutical product destruction on the website of the Drug Administration of Vietnam for reference purpose.”

15. Point b Clause 2 of Article 18 is amended as follows:

“b) Formulate plans to collect pharmaceutical product/pharmaceutical starting material samples for quality inspections carried out at facilities in charge of production, preparation, import, export, storage, wholesaling, retail and use of pharmaceutical products within provinces and cities and present those plans to the provincial People’s Committees for consideration, approval and allocation of budget for plan implementation within the Committees’ competence;”.

16. Point a Clause 13 of Article 18 is amended as follows:

“a) Central pharmaceutical product testing facilities (National Institute of Drug Quality Control, Institute of Drug Quality Control of Ho Chi Minh City, National Institute for Control of Vaccines and Biologicals):

- Analyze and test samples to identify the quality of manufactured, circulated and used pharmaceutical products/pharmaceutical starting materials; report the test results to the Ministry of Health (Drug Administration of Vietnam) and the local Department of Health;

- Research, compile and publish the list of reference materials (including those of impurities) on websites of the institutes and the Drug Administration of Vietnam for analyses and tests on manufactured, imported, circulated and used in Vietnam;

- The National Institute of Drug Quality Control and the Institute of Drug Quality Control Ho Chi Minh City have the responsibility to provide pharmaceutical product testing centers in assigned provinces with physical and electronic copies of pharmaceutical product/pharmaceutical starting material quality standards;

- The National Institute for Control of Vaccines and Biologicals, on an annual basis, review and evaluate vaccine/biological quality trends and present the evaluation to the Drug Administration of Vietnam, which will review and present it to the Ministry of Health for promulgation of guidelines for lot release testing of vaccines and biologicals which are seria containing antibodies and derivatives of human blood and plasma; the scope of work shall include the following elements:

+ A lot release testing policy and policy on reduced testing or exemption from testing of vaccines and biologicals that have been assessed and issued with the Batch Release Certificate by the Stringent Regulatory Authorities.

+ Criteria to be tested upon testing for issuance of the quality certificate, time limit for issuance of the certificate of quality to each vaccine/biological; and

+ Specimen of the lot summary protocols for each type of vaccine/biological.

Update information about issuance of quality certificates for vaccines and biologicals which are seria containing antibodies and derivatives of human blood and plasma on websites of the institutes and the Drug Administration of Vietnam.”

17. Point a Clause 5 of Article 18 is added as follows:

Recover sampling fees returned by trading establishments and costs of substandard pharmaceutical product/pharmaceutical starting material sample testing in accordance with laws”.

18. Point b Clause 5 of Article 18 is added as follows:

“- Recover sampling fees returned by trading establishments and costs of substandard pharmaceutical product/pharmaceutical starting material sample testing in accordance with laws.”

19. Clause 8 Section I in the Appendix I is amended as follows:

“8. Sampling of herbal materials

1. If herbal materials or partially processed herbal materials, including animals and plants (dried medicinal plants and parts thereof) and minerals are regarded as homogeneous, samples thereof shall be taken as prescribed in Section I Clause 9 “r plan” of this Appendix.

2. The sampling for herbal material quality control by state-owned pharmaceutical product quality inspection authorities shall comply with WHO’s Quality control methods for herbal materials 2011. If an herbal material batch shows any sign of non-uniformity, the sampling shall be carried out as prescribed in Point 1 of this Clause.”

20. An additional Form No. 09 in the Appendix III Lot summary protocols is enclosed with this Circular.

Article 2. Effect

This Circular comes into force from March 16, 2020.

Article 3. Responsibility for implementation

The Director General of the Drug Administration of Vietnam, Chief of the Ministry Office, Chief Ministerial Inspector, heads of units affiliated to the Ministry of Health, provincial Departments of Health, pharmacy business establishments, other related authorities, organizations and individuals have the responsibility to implement this Circular.

Difficulties that arise during the implementation of this Circular should be reported to the Ministry of Health (Drug Administration of Vietnam) for consideration and solution./.

|

|

PP. THE MINISTER |

APPENDIX I

GUIDELINES FOR SAMPLING OF

PHARMACEUTICAL PRODUCTS AND PHARMACEUTICAL STARTING MATERIALS FOR QUALITY

VERIFICATION

(Enclosed with the Circular No. 11/2018/TT-BYT dated May 04, 2018 of the

Minister of Health)

I. Sampling procedures and sampling operations

1. Sampling tools

All sampling tools and implements should be made of inert and clean materials, which should be suitable for each sample type, ensure no effect on sample quality, prevent impurities that cause contamination of samples or cross-contamination and ensure safety of sampler (see Section III).

2. Quantity of samples taken

2.1. The quantity of sample taken for analytical and retention purposes should be calculated according to inspection requirements, pharmaceutical product quality standards, applied pharmaceutical starting materials and testing methods but should be sufficient to perform tests to obtain accurate and reliable results.

2.2. Two samples are usually taken from each consignment (one for analytical purpose and one for retention purpose). Where necessary, the number of analytical samples and retention samples may be more than two to be sufficient for testing and retention at relevant organizations.

3. Sampling operations

3.1. Sampling principles:

- Depending on the inspection purpose and each type of product, the sampler should decide to adopt an appropriate sampling method.

- The sampling process should be appropriately supervised and documented. Any signs of non-uniformity or deterioration of pharmaceutical products and containers should be documented.

- The sampling procedure should be such that non-uniformity of pharmaceutical products in each sampling unit and entire consignment can be detected. Signs of non-uniformity include differences in shape, size or colour of particles in crystalline, granular or powdered solid substances; moist crusts on hygroscopic substances; deposits of solid pharmaceutical product in liquid or semi-liquid products; and stratification of liquid products.

- Pooling of the samples from the different portions should be avoided, because this can mask contamination, low potency or other quality problems. Separate samples should be formed from these portions and containers.

- For finished pharmaceutical products, the sampling procedure should take account of the official and non-official tests required for the individual dosage form (e.g. tablets or parenteral preparations). Non-official tests could include testing for adulteration and counterfeiting.

- It is not recommended to mix the pharmaceutical product removed from a container directly with the one left in that container.

3.2. Sampling procedures

- Carry out physical inspection of the consignment: segregate containers by each type of product and consignment, segregate containers that show any signs of deterioration and do not ensure cleanliness for inspection or sampling. Reject unlabelled sampling units.

- Take sampling units from the consignment of products, open containers to take original samples and reseal the containers from which the samples were taken. Ensure that the quantity of materials in the original samples is sufficient to prepare next samples.

- Gently mix original samples into separate samples of each sampling unit.

- Gently mix separate samples into a common sample.

- Form final samples: take equal fractions from the common sample to form final samples, including analytical samples and retention samples.

3.3. Analytical samples and retention samples should be placed in sealed and labeled containers. A sample container should be labeled with name of the pharmaceutical product, name of the manufacturer, lot number, expiry date, number of containers from which samples were taken, place of sampling, number of samples taken (if samples taken are pharmaceutical starting materials for manufacture of narcotic drugs and psychotropic drugs, precursors used as pharmaceutical products and starting materials for manufacture of radiopharmaceuticals), date of sampling and storage conditions in accordance with the sampling record.

3.4. After the sampling is done, analytical samples and retention samples should be separately sealed to ensure their safety during transportation. The seal should clearly specify the date of sampling and bear at least signatures of the sampler and the representative of the establishment where the sample was taken.

Where necessary, the remainder of the sampling interval should be also sealed to prevent tampering of pharmaceutical products and pharmaceutical starting materials.

3.5. Make a sampling record: The sampling record should contain the batch number, date and place of sampling, storage conditions, notes on possible abnormalities, any other relevant observations and at least the name and signature of the sampler and representative of the establishment where the sample was taken.

In the cases where the quality inspectorate takes samples, the record is required to bear the signature of the inspectorate's chief.

In case the representative of the establishment where the sample was taken fails to sign the record, the record should bear the signatures of the sampler and witness.

The record should be made into three copies, which are kept at the establishment where the sample was taken, testing authority and pharmaceutical product quality inspecting authority respectively.

4. Sampling of pharmaceutical starting materials

4.1. In case the material is placed in one container only:

a) Take samples of the solid material: take original samples in different locations of the container (at the top, the bottom or in the middle). If the original samples do not show any visual signs, gently mix them into separate samples.

b) Take samples of the liquid or semi-solid material: if the material is non-homogeneous, gently mix it before sampling. For example, a stratified liquid may be stirred or a solid deposit in a liquid may be dissolved by gentle warming and stirring.

4.2. In case the consignment of material is placed in multiple containers:

Depending on the sampling purpose, uniformity and quality of the consignment of material, adopt an appropriate sampling method according to Section I Clause 9 of this Appendix.

5. Sampling of unpackaged semi-finished products

These products include powdered pharmaceutical products, solutions, syrups, ointments, granules, tablets, injections, etc. that are transported in large containers to the packaging facility. Samples shall be taken from each consignment as follows:

1. If the consignment of products is contained in 1 - 2 containers, open the two containers. If the consignment of products is contained in more than 3 containers, open the three containers. Take at least 3 original samples in different locations of each container.

2. Mix original samples into a common sample, and then form final samples, including analytical and retention samples.

6. Sampling of packaging materials

Samples of packaging materials shall be taken as prescribed in Section 1 Clause 9 of this Appendix.

7. Sampling of finished pharmaceutical products

7.1. Take samples of finished pharmaceutical products to inspect or control quality:

a) Samples should be taken at random and at different locations of the consignment.

b) According to the pharmaceutical product quality standard, the quantity of pharmaceutical product taken should be sufficient to allow for testing and retention. If information is insufficient for accurate calculation of the quantity of pharmaceutical product to be taken, consider the minimum quantity of finished pharmaceutical products provided in Section V of this Appendix.

c) Sampling procedures should be completed according to the guidelines provided in Section II of this Appendix.

7.2. Take samples to carry out visual inspection upon import of pharmaceutical products: the quantity of sample taken to carry out visual inspection is specified in Section IV of this Appendix.

8. 8. Sampling of herbal materials

1. If herbal materials or partially processed herbal pharmaceutical products, including animals and plants (dried medicinal plants and parts thereof) and minerals are regarded as homogeneous, samples thereof shall be taken as prescribed in Section I Clause 9 “r plan” of this Appendix.

2. The sampling for herbal material quality control by state-owned pharmaceutical product quality inspection authorities shall comply with WHO’s Quality control methods for herbal materials 2011. If an herbal material batch shows any sign of non-uniformity, the sampling shall be carried out as prescribed in Point 1 of this Clause.

9. Sampling plans for pharmaceutical starting materials and packaging materials

9.1. Before sampling, the sampler should check the integrity and deterioration of the container, and uniformity of products in each sampling unit.

9.2. Sampling should be carried out according to one of the three sampling plans provided in Table 1 below.

Table 1: Values of n, p or r for the N sampling units

|

Value of n, p, r |

Values of N |

||

|

n plan |

p plan |

r plan |

|

|

2 |

Up to 3 |

Up to 25 |

Up to 2 |

|

3 |

4 - 6 |

25 - 56 |

3 - 4 |

|

4 |

7 - 13 |

57 - 100 |

5 - 7 |

|

5 |

14 - 20 |

101 - 156 |

8 - 11 |

|

6 |

21 - 30 |

157 - 225 |

12 - 16 |

|

7 |

31 - 42 |

|

17 - 22 |

|

8 |

43 - 56 |

|

23 - 28 |

|

9 |

57 - 72 |

|

29 - 36 |

|

10 |

73 - 90 |

|

37 - 44 |

a) The n plan

The “n plan” should be used only when the material to be

sampled is considered uniform and is supplied from a recognized source. Samples

can be withdrawn from any part of the container (usually from the top layer). The

“n plan” is based on the formula n = 1 +![]() , where N is the number of sampling units in

the consignment. The value of n is obtained by simple rounding. Original

samples are taken from n sampling units selected at random and these are

subsequently placed in separate sample containers. If the results are

concordant, the original samples are combined into a final, common sample from

which an analytical sample is prepared, the remainder being kept as a retention

sample.

, where N is the number of sampling units in

the consignment. The value of n is obtained by simple rounding. Original

samples are taken from n sampling units selected at random and these are

subsequently placed in separate sample containers. If the results are

concordant, the original samples are combined into a final, common sample from

which an analytical sample is prepared, the remainder being kept as a retention

sample.

b) The p plan

The “p plan” may be used when the material is uniform, is

received from a recognized source and the main purpose is to test for identity.

The p plan is based on the formula p = 0.4![]() , where N is the number of sampling units. The

figures for p are obtained by rounding up to the next highest integer. Original

samples are taken from each of the N sampling units of the consignment and

placed in separate sample containers. These original samples are visually

inspected and tested for identity. If the results are concordant, p common

samples are formed by appropriate pooling of the original samples (if

necessary).

, where N is the number of sampling units. The

figures for p are obtained by rounding up to the next highest integer. Original

samples are taken from each of the N sampling units of the consignment and

placed in separate sample containers. These original samples are visually

inspected and tested for identity. If the results are concordant, p common

samples are formed by appropriate pooling of the original samples (if

necessary).

c) The r plan

The “r plan” may be used when the material is suspected to

be non-uniform and/or is received from a source that is not well known, herbal

medicinal products or partially processed herbal medicinal products. This plan

is based on the formula r = 1.5![]() , where N is the number of sampling units. The

figures for r are obtained by rounding up to the next highest integer.

, where N is the number of sampling units. The

figures for r are obtained by rounding up to the next highest integer.

Original samples are taken from each of the N sampling units of the consignment and placed in separate sample containers. These original samples are visually inspected and tested for identity. If the results are concordant, r samples are randomly selected and individually subjected to testing. If these results are concordant, the r samples are combined for the retention sample.

9.3. The abovementioned sampling plans are not recommended for sampling of starting materials for identification tests. The GMP-WHO rules shall apply instead.

II. Sampling steps

1. Bulk liquid products

The steps to be considered when sampling bulk liquid products are as follows:

- Read and understand the precautions to be observed for the safe handling of the material.

- Gather together the required sampling equipment (sampling tube or weighted sampling can, sample bottles and labels) and check that all the required items are clean.

- Locate the batch.

- Examine the container(s) for signs of contamination of the batch. Record any faults.

- Investigate and clarify the sources of and reasons for any faults before proceeding. Record any faults.

- Investigate and clarify the sources of and reasons for any faults before proceeding.

- Choose a liquid-sampling tube of size and orifice suitable for the viscosity of the liquid being sampled.

- Sample the liquid, suspension or emulsion (well stirred, if appropriate) by slowly pushing the open sampling tube vertically down- wards through the liquid so that material is collected from each layer.

- Seal the tube, withdraw it from the bulk liquid, and allow liquid adhering to the outside of the tube to drain. Transfer all the contents of the tube to a clean, labelled sample bottle.

- Repeat steps 8 and 9 until sufficient samples for analytical and retention purposes have been obtained.

- Seal the sample bottle.

- Reseal the container from which the samples were withdrawn and label as “sampled”.

- Wipe clean the sampling spear if required, observing the safety precautions.

- Repeat steps 12–18 for each chosen container.

- Clean the sampling spear using the recommended cleaning procedure.

- Deliver the analytical samples to the laboratory and the reserve samples to the retention sample store. Report any aspects of the sampling that should be brought to the attention of the analyst or the inspector.

- Check supplier certificate versus the specifications, if applicable.

2. Powdered starting material

The steps to be considered in sampling a powdered starting material are as follows:

- Read and understand the precautions to be observed for the safe handling of the material.

- Gather together the required sampling equipment (sampling spear, sample bottles and labels) and check that all items are clean.

- Locate the consignment and count the number of containers.

- Examine all the containers for obvious differences and signs of damage. Record any faults.

- Examine all the labels for obvious differences and signs of changes, including obliterations and mislabelling. Record any faults.

- Segregate any damaged containers and those with suspected spoiled contents for separate examination. These should then be referred or rejected and dealt with accordingly.

- Segregate any containers with different batch numbers and treat these separately.

- Number the remaining containers.

- Choose the appropriate sampling plan (n, p or r).

- Choose the containers to be sampled in accordance with the requirements of the chosen plan (by the use of random number tables, by drawing lots or by the use of a random number generator if applicable).

- Open the containers one at a time and inspect the contents. Record any differences.

- Choose a suitable, clean sampling spear and plunge this (gates closed) into the powder so that the point of the spear reaches the bottom of the container.

- Open the gates to allow the powder to enter the spear cavities, then reclose them.

- Withdraw the spear from the container and transfer the spear contents to a labelled sample bottle.

- Repeat steps 12–14 until sufficient material has been collected for analytical and retention requirements.

- Seal the sample bottle.

- Reseal the container from which the samples were withdrawn and label as “sampled”.

- Wipe clean the sampling spear if required, observing the safety precautions, before sampling the other chosen containers.

- Repeat steps 12–18 for each chosen container.

- Clean the sampling spear using the recommended cleaning procedure.

- Deliver the analytical samples to the laboratory and the reserve samples to the retention sample store. Report any aspects of the sampling that should be brought to the attention of the analyst or the inspector.

- Check supplier certificate versus the specifications, if applicable.

3. Packaging materials

The steps to be considered in sampling packaging materials are as follows:

- Check the consignment against any associated documentation.

- Check transit containers for the following and report any deviations as necessary:

+ Correct identification;

+ integrity of seal, if appropriate; and

+ Absence of physical damage.

- Obtain the required sample from the required number of containers, bearing in mind the special considerations for sampling packaging materials noted in Section I Clause 9 of this Appendix.

- Place the sample units into identified appropriate sample containers.

- Identify the consignment containers that have been sampled.

- Note any special situations found during the sampling process (e.g. rogue items or component damage). Report any such observations as necessary.

- Remove all sampled material pallets or containers from the sampling area together with all documentation.

- Check supplier certificate versus the specifications, if applicable.

4. Finished products

The following steps should be considered when sampling finished products:

- Determine the number of pallets per batch in the consignment.

- Calculate the number of pallets according to the number of sampling units to carry out visual inspection:

+ Check condition of pallet and packaging for integrity of outer packaging material.

+ Check outside of goods on the pallets for general cleanliness.

+ Check that the overall labelling of the pallets matches the packing list.

+ Count, categorize and record the number of defects.

- Count the total number of transport packs on the number of pallets present and verify the total against the packing list.

- From the number of pallets, work out the number of transport packs to be sampled:

+ Check condition of boxes for integrity of packaging material.

+ Check for cleanliness of boxes.

+ Check the labelling of the boxes for damage.

+ Check the boxes for overall damage.

+ Check the labels for spelling mistakes.

+ Check the labels for manufacturing and expiry dates.

+ Count, categorize and record the number of defects.

- From the number of boxes selected, work out the number of unit packs to examined visually:

+ Check condition of the containers for integrity of packaging material.

+ Check for cleanliness of containers.

+ Check condition of containers for shape and colour.

+ Check the labelling of containers for damage.

+ Check the boxes for overall damage.

+ Check the labels for spelling mistakes.

+ Check the labels for manufacturing and expiry dates.

+ Count, categorize and record the number of defects.

- From the number of containers selected, determine the number of containers to be taken for physical and chemical testing and for retention.

- Check the supplier certificate against the specifications, if applicable.

III. Types of sampling tools

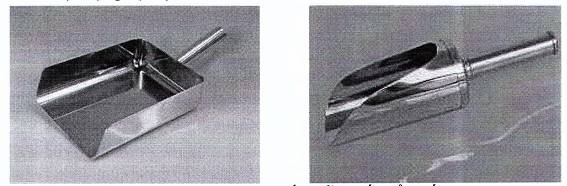

Figure 1. Sampling scoops for solids

Figure 2. Typical dip tube

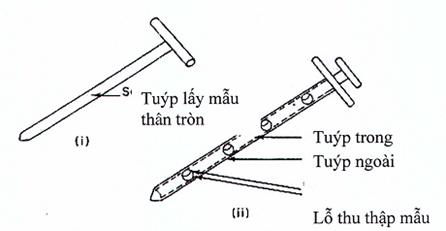

Figure 3. Typical sample thieves

(i) The plug thief (Figure 3.i) typically consists of a hollow tube with an inner rod that has a tip on the end to allow the thief to enter the powder bed in the closed position. Pointed tips distort the powder bed less than blunt-tipped probes. Some thieves have a locking device that allows the sample volume to be set to the required sample weight, thereby reducing the weight variation in the sample population.

(ii) A chamber thief (Figure 3.ii) generally consists of two concentric tubes; the inner tube is solid except for the chambers in which the sample is collected. The outer tube is hollow with openings that can be aligned with the chambers in the inner tube. A well-designed thief will have a sharp end to minimize disruption to the powder bed.

Note: When it is inserted into a static powder blend a thief will distort the bed by carrying pharmaceutical product from the upper layers of the blend to the lower layers. The magnitude of this distortion can depend on whether the thief is inserted into the blend with a smooth, jerky or twisting action. Therefore, staff should be trained in using the appropriate technique.

The angle at which the thief enters the powder bed can also influence sampling error. If a thief is inserted into the powder bed vertically, it can extract samples of different particle size from those that would be obtained using the same thief inserted at an acute angle. In addition, the orientation of a chamber thief in relation to the powder bed (i.e. whether the chamber is at the top, the bottom or in the middle of the thief) may also influence the sampling error.

Sampling error can also be affected by bed depth, as the static pressure of the bulk blend forces the material into the sample chamber(s). This pressure is far greater at the bottom of a large container than it is in the middle or at the top. It is quite possible that the same thief could extract samples of different particle size from the top or bottom of a static powder blend.

Figure 4. Weighted container

For taking samples from large tanks and storage vessels, a container in a weighted carrier can be used. The container is designed such that it can be opened at the required depth. Marks on the cord used for lowering the container can be used to determine when the correct sampling depth has been reached.

Figure 5. Typical sampling spears

A: Closed spear for sampling large grains such as maize

B: Closed spear for sampling small grains such as wheat

C: Open spear

D: Double-tube spear

Sampling spears generally have a maximum external diameter of about 12 mm, but can be up to 25 mm in diameter and should be 40–45 cm in length.

IV. Number of sampling units from batches of finished pharmaceutical products to be taken for visual inspection (ISO 2859-1)

|

Lot size Number of sampling units from batches/lots |

Number of sampling units from batches of finished pharmaceutical products to be taken for visual inspection |

|

2 to 8 |

2 |

|

9 - 15 |

3 |

|

16 - 25 |

5 |

|

26 - 50 |

8 |

|

51 - 90 |

13 |

|

91 - 150 |

20 |

|

151 - 280 |

32 |

|

281 - 500 |

50 |

|

501 - 1200 |

80 |

|

1201 - 3200 |

125 |

|

3201 - 10000 |

200 |

|

10001 - 35000 |

315 |

|

35001 - 150000 |

500 |

|

150001 - 500000 |

600 |

|

Over 500001 |

1250 |

V. Number samples taken for quality inspection

Number of samples of pharmaceutical products and pharmaceutical starting materials taken for quality inspection (excluding samples taken for retention purpose):

|

No. |

Dosage form |

Type, specifications |

Quantity |

|

1 |

Tablets, capsules, film coated tablets |

1 active ingredient |

80 tablets/capsules |

|

≥ 2 active ingredients |

120 tablets/capsules |

||

|

2 |

Solutions |

≥ 100 ml |

20 bottles (vials) |

|

10 - 100 ml |

30 bottles (vials) |

||

|

5ml - 10ml |

50 bottles (vials) |

||

|

< 5ml |

100 bottles (vials) |

||

|

3 |

Granules, powders |

Packaged in single-dose or multiple-dose |

~ 100 gram |

|

Hard pills, soft pills |

> 0.5 g/pill |

120 pills |

|

|

0.1 - 0.5 g/pill |

200 pills |

||

|

< 0,1 g/pill |

500 pills |

||

|

4 |

Medicinal liquor |

≤ 650 ml |

7 bottles |

|

> 650 ml |

5 bottles |

||

|

5 |

Intravenous fluids |

≥ 250 ml |

20 bottles |

|

100 ml - 250 ml |

25 bottles |

||

|

< 100 ml |

50 bottles |

||

|

Syringes |

1ml |

150 syringes |

|

|

≥ 2 ml |

120 syringes |

||

|

Distilled water for injection |

2 ml |

250 ampoules |

|

|

5 ml |

100 ampoules |

||

|

10 ml |

80 ampoules |

||

|

6 |

Eye drops |

≤ 2ml/100mg |

100 vials (tubes) |

|

> 2ml/100mg |

80 vials (tubes) |

||

|

7 |

Topical ointments, creams, gels |

≤ 100mg |

30 vials (tubes) |

|

> 100mg |

40 vials (tubes) |

||

|

8 |

Powders for injection |

< 100 mg |

150 vials |

|

100 - 450 mg |

120 vials |

||

|

> 450 mg |

100 vials |

||

|

9 |

Massage oil |

1 - 2 ml |

30 vials |

|

≥ 5 ml |

20 vials |

||

|

10 |

Medicinal extract |

Various forms |

~100g |

|

11 |

Herbal materials |

Containing oil |

250 g |

|

Not containing oil |

100 g |

||

|

12 |

Oil |

Various forms |

150 ml |

|

13 |

Vaccines, biologicals |

Various forms |

In accordance with the manufacturer's regulations |

|

14 |

Materials |

Precious materials |

20 g |

|

Antibiotic materials |

50 g |

||

|

Materials for manufacture of narcotic drugs and psychotropic drugs, precursors |

10g |

||

|

Normal materials |

100 g |

||

|

Plastic beads |

200 g |

||

|

15 |

Infusion sets |

Various forms |

30 sets |

|

16 |

Hollow glass tubes |

2 ml |

500 tubes |

|

≥ 5 ml |

300 tubes |

||

|

17 |

Bottles for intravenous fluids |

Various forms |

10 bottles |