Nội dung toàn văn Circular 15/2020/TT-BCT National Technical Regulation on design requirements petrol filling stations

|

MINISTRY OF

INDUSTRY AND TRADE |

SOCIALIST

REPUBLIC OF VIETNAM |

|

No. 15/2020/TT-BCT |

Hanoi, June 30, 2020 |

CIRCULAR

NATIONAL TECHNICAL REGULATION ON DESIGN REQUIREMENTS FOR PETROL FILLING STATIONS

Pursuant to Law on Standards and Technical regulations dated June 29, 2006;

Pursuant to Decree No. 127/2007/ND-CP dated August 1, 2007 of the Government on elaborating to Law on Technical Standards and Regulations and Decree No. 78/2018/ND-CP dated May 16, 2018 on amendments to Decree No. 127/2007/ND-CP dated August 1, 2007 of the Government on elaborating to Law on Technical Standards and Regulations;

Pursuant to Decree No. 98/2017/ND-CP dated August 18, 2017 of the Government on functions, tasks, powers, and organizational structure of the Ministry of Industry and Trade;

Pursuant to Decree No. 08/2018/ND-CP dated January 15, 2018 of the Government on amendments to a number of Decrees relating the business investment conditions under state management of the Ministry of Industry and Trade;

At request of Director General of Domestic Markets Department;

Minister of Industry and Trade promulgates Circular on National Technical Regulation on design requirements for petrol filling stations

Article 1. Attached to this Circular is the National Technical Regulation on design requirements for petrol filling stations

No. QCVN 01:2020/BCT.

Article 2. Entry into force

1. This Circular comes into force from January 1, 2021./.

2. This Circular replaces Circular No. 11/2013/TT-BCT dated June 18, 2013 on National Technical Regulation on design requirements of petrol filling stations and Circular No. 47/2015/TT-BCT dated December 11, 2015 on National Technical Regulation on design requirements of floating petrol filling stations.

Article 3. Responsibilities for implementation

1. Domestic Market Department shall be responsible for implementation of this Circular on a nationwide scale.

2. Departments of Industry and Trade of provinces and central-affiliated cities shall be responsible for guiding and examining implementation of this Circular in administrative divisions under their management and reporting implementation results to Ministry of Industry and Trade as per the law.

3. Chief of the Ministry Office, Director General of Domestic Market Department, Director General of Science and Technology Department, Directors of Departments of Industry and Trade in provinces and central-affiliated cities, heads of relevant agencies, organizations and individuals are responsible for implementation of this Circular./.

|

|

PP. MINSTER |

QCVN 01:2020/BCT

NATIONAL TECHNICAL REGULATION ON DESIGN REQUIREMENTS FOR PETROL FILLING STATIONS

PREFACE

QCVN 01:2020/BCT is prepared by the Drafting Board of National Technical Regulation on design requirements for petrol filling stations, approved by Domestic Market Department and issued by Ministry of Industry and Trade under Circular No. 15/2020/TT-BCT dated June 30, 2020.

This Regulation replaces Regulation on design requirements of petrol filling stations No. QCVN 01:2013/BCT and Regulation on design requirements of floating petrol filling stations No. QCVN 10:2015/BCT..

NATIONAL TECHNICAL REGULATION ON DESIGN REQUIREMENTS FOR PETROL FILLING STATIONS

Chapter I

GENERAL PROVISIONS

Article 1. Scope

This Regulation prescribes basic technical requirements in new construction, establishment, renovation, expansion or reformation of above-ground and floating petrol filling stations owned by the Socialist Republic of Vietnam.

Article 2. Regulated entities

This Regulation applies to:

1. Organizations and individuals constructing new, establishing, upgrading, expanding and reforming above-ground and floating petrol filling stations.

2. Traders operating in petrol industries.

3. Other relevant organizations and individuals.

Article 3. Term interpretation

In this Regulation, terms below are construed as follows:

1. “petrol filling station” refers to a place where fuel is retailed to terrestrial or waterborne transportation via fuel dispensers. A petrol filling station may combine sale of bottled liquefied petroleum gas (LPG), lubricants and provision of other services for people and transportation.

“above-ground petrol filling station” refers to a petrol filling station constructed totally or partially above-ground.

“floating petrol filling station” refers to a petrol filling station constructed fixed above the water, a reformed steel hull vessel or barge or other floating craft.

2. “other services” refer to services provided for people and transportation namely: car wash, vehicle service and maintenance, parking lot, rest stop, convenient store, ATM, battery charging or swapping stations for electric vehicles.

3. “point-of-service”

Refers to where fuel dispensers are located and goods (lubricants, bottled LPG, etc.) are sold.

4. “other work items”

Consist of work items providing other services, break rooms between shifts, product display rooms, working offices at stores, restrooms, staff spaces, generator installation areas, refuse collection areas, water supply areas, etc.

5. “forecourt”

Refers to an area used solely for installation of fuel dispensers and payment terminals (if any) and shall be at a higher elevation compared to general premises of the station.

6. “mechanical pipeline”

Refers to pipelines (including pipes and adapters) and in-line components to carry gasoline and petroleum gas.

A mechanical pipeline consists of: fill pipes (to carry petrol from fuel trucks into tanks), enclosed couplings (installed fixed at the end of inlet pipes to connect with pipes from fuel trucks to carry petrol into tanks), outlet pipes (to carry petrol from tanks to fuel dispensers) and vapor pipes (to carry petrol vapor from tanks to breather valves, from fuel dispensers to tanks or from tanks to fuel trucks).

7. “breather valve”

Refers to a device that controls residual pressure (positive pressure) and vacuum pressure (negative pressure) in a tank to guarantee safety for the tank and prevent loss due to evaporation during transportation process.

8. “enclosed filling”

Refers to a method of carrying petrol from fuel trucks to fuel tanks in an enclosed manner via enclosed couplings.

9. Wastewater of petrol filling stations consists of:

a) Petrol-contaminated wastewater is generated from: car wash water, car wash premise cleaning water, vehicle maintenance water, fuel tank cleaning water, rainwater overflowing from areas potentially contaminated with petrol.

b) Domestic wastewater not contaminated with petrol and surface water.

10. “vapor recovery system”

Refers to a system that collects and restricts release of petroleum vapor into the atmosphere when unloading fuel into tanks or selling to transportation at petrol filling stations.

Article 4. Reference documents

Following reference documents are necessary for adoption of this Regulation, in case the documents below are amended or replaced, the new versions shall prevail.

TCVN 4090:1985 Petroleum storage, stations and pipelines – Primary oil pipes and oil products – Design standards.

TCVN 5684:2003 Fire safety for petroleum facilities and petroleum products – General requirements.

TCVN 4054:2005 Automobile roads – Design requirements.

TCVN 5334:2007 Electrical equipment for petroleum storage and products - Safety requirements in design, installation and use.

TCVN 3890:2009 Fire safety and firefighting equipment for buildings and constructions – Equipment, placement, examination and maintenance.

TCVN 5307:2009 Petroleum storage and products - Design requirements.

QCVN 29:2010/BTNMT National Technical Regulation on wastewater of petroleum storage and filling stations.

QCVN 72:2013/BGTVT National Technical Regulation on classification4 and construction norms of inland waterway vehicles; Amendment No. 1:2015 of QCVN 72:2013/BGTVT; Amendment No. 2:2018 of QCVN 72:2013/BGTVT;

QCVN 07-6:2016/BXD National Technical Regulation on technical infrastructural constructions for petroleum and gas supply.

TCVN 6223:2017 Liquefied petroleum gas (LPG) stations – General safety requirements.

QCVN 01:2019/BXD, National Technical Regulation on construction planning.

QCVN 06:2020/BXD, National Technical Regulations on fire safety for houses and work items.

Chapter II

TECHNICAL REGULATIONS

Article 5. Classification of petrol filling stations

Petrol filling stations shall be classified based on the petrol gross tonnage as specified in Schedule 1.

Schedule 1: Classification of petrol filling stations

|

Station classification |

Gross tonnage (m3) |

|

|

Above-ground petrol filling stations and petrol filling stations constructed fixed on water surface |

Petrol filling stations floating on water surface (vessels, steel hull ships and other floating crafts) |

|

|

Level 1 |

From 150 to 210 |

From 100 to 200 |

|

Level 2 |

Exceeding 100 to less than 150 |

From 16 to less than 100 |

|

Level 3 |

Less than or equal to 100 |

Less than 16 |

Article 6. General requirements

1. Construction and anchoring position of petrol filling stations, services of petrol fill stations must satisfy traffic safety, construction safety, environment hygiene, and fire safety as per applicable law.

2. Technological devices for payment must be used outside of hazardous zone unless they are explode-proof.

3. Regarding petrol filling stations selling bottled LPG within the point-of-service, comply with safety regulations under TCVN 6223:2017 Liquefied Petroleum Gas station – General safety requirements.

4. Petroleum filling stations must develop oil spill prevention as per the law.

5. Comply with fire safety requirements according to regulations and law on fire prevention and fighting.

6. Regulations applied to an above-ground petrol filling station

In addition to regulations under Clauses 1, 2, 3, 4, and 5 of this Article, an above-ground petrol filling station must satisfy following requirements:

a) Distance between work items in an above-ground petrol filling station must not be lower than values specified under Schedule 2.

Schedule 2. Minimum distance between work items in a petrol station

|

Work items |

Underground tank (m) |

Fuel dispenser (m) |

Point-of-service (m) |

|

1. Underground tank |

0,5 |

No regulations |

2 |

|

2. Enclosed coupling |

No regulations |

No regulations |

3 |

|

3. Fuel dispenser |

No regulations |

No regulations |

No regulations |

|

4. Other work items that may generate sparks |

2 |

2 |

2 |

|

Note: 1) Minimum distance from fuel tanks to point-of-service whose walls have no doorways or windows is not regulated. 2) Minimum distance from fuel dispensers to building walls is not regulated as long as installation, operation and repair are guaranteed. |

|||

b) Structural components and materials used to construct point-of-service and other work items must have fire resistance category of level I or II according to QCVN 06:2020/BXD National Technical Regulation on fire safety for buildings and constructions; must guarantee load-bearing capacity when affected by load and corrosion of surrounding environment during the useful life of the structure.

c) Roads and parking lots for vehicles to purchase and unload fuel must satisfy following requirements:

- Width of a lane must not be less than 3.5 m. Two-lane driveway must not be narrower than 6.5 m.

- Parking lots for fuel loading and unloading must not be coated with materials containing asphalt.

d) Petrol filling stations situated adjacent to other constructions must be covered by walls no shorter than 2.2 m (compared to the base of the stations) made of non-flammable materials. If walls of civil work items and other constructions situated outside of the stations (excluding manufacturing facilities that generate fire or sparks and public constructions) and having level I or II fire resistance category are fire walls, minimum distance from the work items to the outer walls of the petrol filling stations is not regulated while applicable construction regulations must be complied with.

dd) Roof of fuel dispenser area (if any) must not be shorter than 4.75 m.

7. Regulations applied to a floating petrol filling station

In addition to regulations under Clauses 1, 2, 3, 4, and 5 of this Article, a floating petrol filling station must satisfy following requirements:

a) Structural components and materials for points-of-service and other work items must have level II or III fire resistance category according to QCVN 06:2020/BXD on National Technical Regulation on fire safety for buildings and construction or QCVN 72:2013/BGTVT National Regulations on classification and building norms of inland waterway vehicles.

b) Storm and flood prevention must be developed, anchoring position for avoiding storm must be identified as per the law. Petrol filling station constructed fixed on water surface must have storm counter, anchoring and evacuation measures as per the law.

Article 7. Classification of hazardous zone of petrol filling stations

Classification of fire hazardous zone for work items in an above-ground petrol filling station is specified in Schedule 3.

Schedule 3. Classification of fire hazardous zone

|

Work item |

Hazardous zone |

|

1. Areas in which petrol is stored and sold: |

|

|

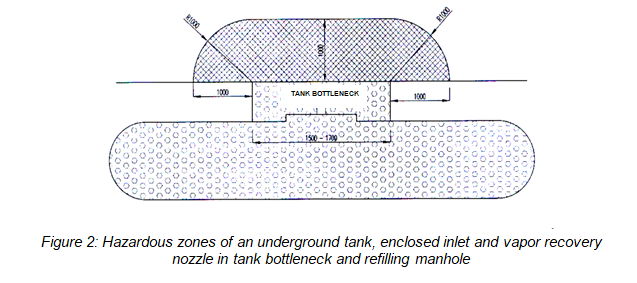

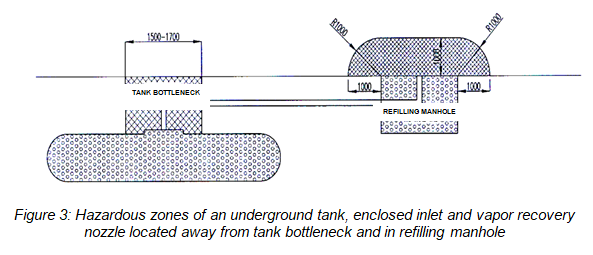

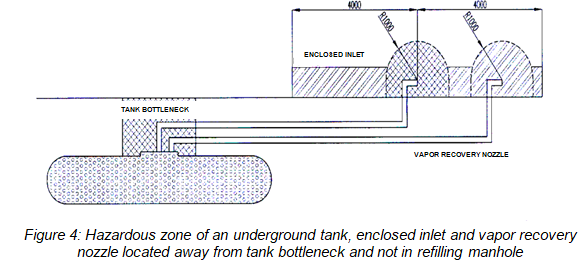

- Fuel tanks, inlet couplings, refilling manhole |

- Figure 2, 3, and 4 |

|

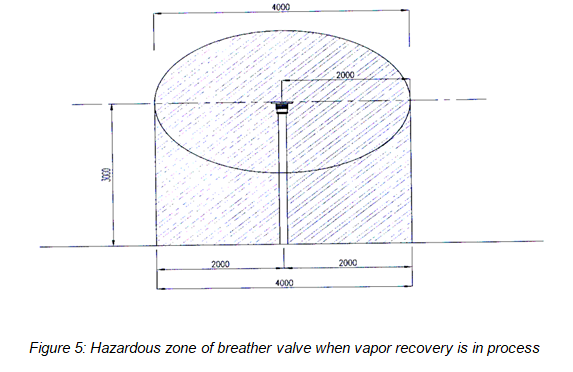

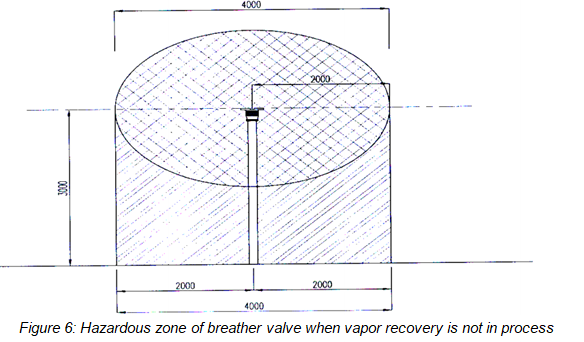

- Breather valve |

- Figure 5 and 6 |

|

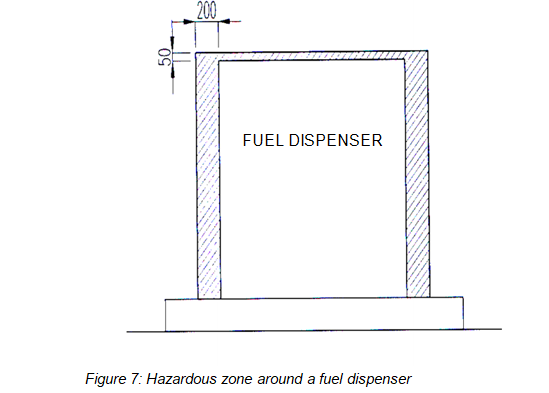

- Fuel dispensers |

- Figure 7 |

|

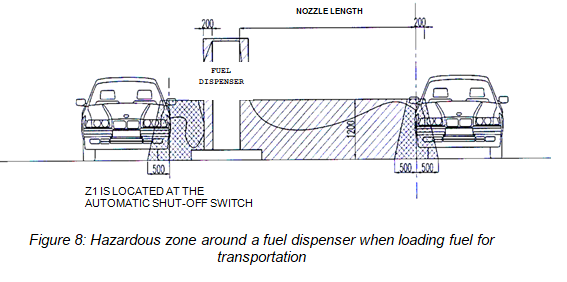

- Fuel dispensers when selling fuel to transportation |

- Figure 8 |

|

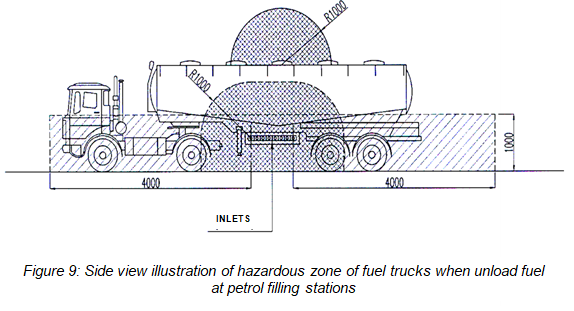

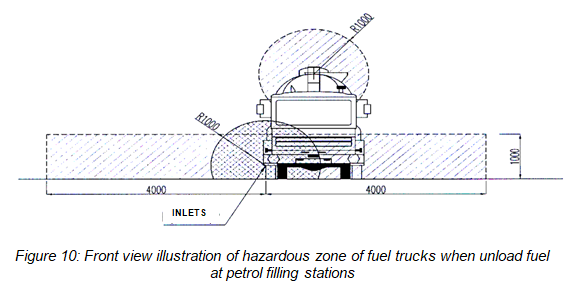

- Vehicles unloading fuel at petrol filling stations |

- Figure 9 and 10 |

|

2. Areas where other petroleum products are stored and sold: |

|

|

- Bottled LPG storage |

- Z1 |

|

- Lubricant storage |

- Z2 |

|

3. Other work items |

- Non-hazardous zone |

|

Note: Definition of fire hazardous zone and elaboration of illustration regarding fire hazardous zones are specified under Annex 1 attached to this Regulation. |

|

Article 8. Fuel tank

1. Regarding above-ground petrol filling stations

a) Fuel tanks must be made from petrol-resistant and non-flammable materials.

b) During installation of fuel tanks at petrol filling stations, comply with following regulations:

- Do not install fuel tanks aboveground.

- Do not install fuel tanks and refilling manholes in or below points-of-service.

- Take into account possibility of tank flotation and adopt tank flotation prevention measures when installing fuel tanks.

- Spread fine sand or soil around the tank area with no less than 0.3 m in thickness.

- Develop and adopt measures to protect structure of fuel tanks installed below driveways.

- Develop measures to eliminate static generated during petrol loading and unloading process in case of non-conductive fuel tanks.

c) Outer layer of an underground steel tank must be coated with an anti-corrosive layer no lower than enhanced level specified under TCVN 4090:1985 Petrol storage, stations and pipelines – Primary oil and oil product pipelines – Design standards.

d) Minimum distance from fuel tanks to structures outside the stations is specified under Schedule 4.

2. Regarding floating petrol filling stations

a) Fuel tanks must be made from petrol-resistant and non-flammable materials.

b) Develop measures to eliminate static generated during petrol loading and unloading process in case of non-conductive fuel tanks.

c) Conduct industrial hygiene on a regular basis and post “không phận sự miễn vào” (no unauthorized personnel) sign where fuel tanks are installed.

Article 9. Fuel dispensers

1. Regarding above-ground petrol filling stations

a) Fuel dispensers in a petrol filling station must be installed:

- In clear spots. In case fuel dispensers are positioned indoors, install in separate spaces with ventilation measures and doors opening outwards.

- To guarantee that transportation can park along the fuel dispensers with ease and without obstructing other transportation.

b) Fuel dispensers must be positioned on forecourt. The forecourt must satisfy following design requirements:

- Elevation: taller than the premises of the parking lot by at least 0.15 m.

- Width: no less than 1.0 m.

- Each end of the forecourt must be at least 0.5 m away from a roof supporting beam or a fuel dispenser.

c) Minimum distance from fuel dispensers to structures outside the stations is specified under Schedule 4.

Schedule 4: Minimum distance from fuel tanks and fuel dispensers to structures outside the stations

|

Work items |

Minimum

distance (m) |

||||

|

Level 1 stations |

Level 2 stations |

Level 3 stations |

|||

|

Manufacturing facilities that generate fire or sparks |

18 |

18 |

18 |

||

|

Crowded area (4) |

50 |

50 |

50 |

||

|

Civil constructions and other constructions outside of the stations (5) |

Fire resistance category (1) |

I, II |

5 |

5 |

5 |

|

III |

15 |

12 |

10 |

||

|

IV, V |

20 |

14 |

14 |

||

|

Cable-electricity lines Telecommunication lines |

- Comply with applicable regulations and law on power grid safety corridor. - Comply with applicable telecommunication laws. |

||||

|

Note: (1) Fire resistance category of constructions shall conform to QCVN 06:2020/BXD, National Technical Regulations on fire safety for houses and work items. (2) Distance for fuel tanks calculated from edges of refilling manholes. (3) Distance for fuel dispensers from center of a fuel dispenser. (4) Crowded areas include: schools, hospitals, stadiums, markets, shopping malls, supermarkets, national exhibits, gas stations, coach stations, ship docks. (5) Distance for civil constructions calculated up to perimeter of the constructions. |

|||||

- Minimum distance specified in Schedule 4 may be reduced by 30% if the stations are installed with vapor recovery system.

- Minimum distance from fuel tanks and fuel dispensers to crowded areas may be reduced down to 25 meters (17 meters in case of installation of vapor recovery system) if petrol filling stations are equipped with fixed or semi-fixed fire protection systems.

2. Regarding floating petrol filling stations

Fuel dispensers in a petrol filling station must be installed:

a) In clear and convenient spots.

b) To guarantee that transportation can park along the fuel dispensers with ease and without obstructing other transportation.

Schedule 5. Minimum distance for floating petrol filling stations to work items

|

Work items |

Minimum safe distance (m) |

||||

|

Level 1 stations |

Level 2 stations |

Level 3 stations |

|||

|

1. Ferry stations, docks, bridges, fish farms, markets |

100 |

100 |

70 |

||

|

2. Manufacturing facilities that generate fire or sparks |

50 |

50 |

30 |

||

|

Civil constructions and other constructions |

Fire resistance category |

I, II |

15 |

12 |

5 |

|

III |

20 |

15 |

10 |

||

|

IV, V |

25 |

20 |

12 |

||

|

Note: In case civil constructions and other constructions specified in the Schedule have minimum fire resistance category of level I, II or III whose wall facing the petrol filling stations are fire walls, minimum distance is not regulated |

|||||

Article 10. Mechanical pipeline

1. Mechanical pipeline of a petrol filling station must be made of petrol-resistant and non-flammable materials. Inner diameter of the pipe must be at least 32 mm. Steel pipelines must be implemented with anti-corrosive measures. Develop measures to eliminate static generated during petrol loading and unloading process in case of non-conductive pipelines.

2. Couplings along the mechanical pipelines must be airtight, mechanically and chemically durable.

3. Mechanical pipelines travelling parallel with each other must be separated from each other by a distance equivalent to diameter of a larger pipe. Regarding pipes connected by flanges positioned parallel with each other, distance between the pipes must be at least equivalent to diameter of the flange plus 3 cm. Regarding pipes connected by flanges positioned in-between pipes that are not connected by flanges, the distance from the outer edge of the flange to the outer edge of the nearest pipe must be at least 3 cm.

4. Distance from the lowest point of sump pumps in fuel tanks which carry fuel to fuel dispensers must be at least 15 cm away from the bottom of the tanks.

5. Fuel must be loaded into tanks in an enclosed manner. Pipes loading fuel into tanks must reach the bottom of the tanks and not be more than 20 cm away from the bottom of the tanks.

6. All fuel tanks must be installed with breather valves. Permit installation of a single breather valve for all tanks containing the same type of fuel.

7. In addition to regulations under Clause 1 to Clause 6 of this Article, mechanical pipeline of an above-ground petrol station must comply with following regulations:

a) Mechanical pipeline must be positioned underground or in covered trenches and tightly wrapped with sand. The wrapping must be at least 15 cm in thickness (In case of entrenched pipelines, the thickness must be at least 5 cm). Permit aboveground installation of mechanical pipes in areas not affected by humans and transportation. Regarding floating petrol filling stations, ensure that mechanical pipelines in the stations are installed in areas not affected by humans and transportation.

Mechanical pipelines in areas with vehicle movement must be installed in underground tubes or in covered trenches wrapped in sand. Both ends of the tubes must be tightly caulked. The pipes must be installed at a depth that does not affect endurance of the entire system.

b) Regarding underground tanks, mechanical pipeline must tip towards the tanks with adequate slope for pumps to operate.

8. In addition to regulations under Clause 1 to Clause 6 of this Article, mechanical pipeline of a floating petrol station must comply with following regulations:

a) Mechanical pipes must be installed in areas not affected by humans and transportation.

b) Distance from the lowest point of sump pumps in fuel tanks which carry fuel to fuel dispensers must be at least 15 cm away from the bottom of the tanks.

c) Regarding pumping technology, when a tank simultaneously provide petroleum for multiple fuel dispensers, each fuel dispenser must have a separate pipe and pipes in tanks must be installed with check valves.

9) Requirements for breather valves

a) Technical specification conforms to structure, volume and operational conditions of tanks. Outlets of a breather valve must point sideways or upwards.

b) Inner diameter of pipes connecting from tanks to breather valves must not be less than 50 mm.

c) Breather valves of the petrol filling station must have separate fire arrestors and direct strike lightning protection system or must be installed within protection range of direct strike lightning protection system of the station.

d) In addition to regulations under Point a to Point c of this Clause, breather valves of an above-ground filling station must satisfy following requirements:

- In case pipes connecting to breather valves are installed along outer walls of a petrol filling station: may bend the pipes to a 45o position relative to the vertical position thereof while ensuring that the distance from the breather valves to the inner walls of the petrol filling station must not be lower than 2 m. This distance shall be reduced to 0.5 m if the station is installed with vapor recovery system.

- In case pipes connecting to breather valves are installed along walls and/or pillars of work items, outlets of the breather valves must be at least 1 m taller than the roof and 3.5 m taller than all types of doors.

dd) In addition to regulations under Point a to Point c of this Clause, breather valves of a floating petrol filling station must ensure that outlets of the breather valves must be at least 1 m taller than the roof of the station.

Article 11. Electrical grid

1. Regarding above-ground petrol filling stations

a) Safety requirements in design, installation and use of electrical equipment in filling stations must conform to TCVN 5334:2007 Electrical equipment of oil and oil product storage – Safety requirements in design, installation and use.

b) In case power generators are used in petrol filling stations, position the generators outside of hazardous zones. Exhaust pipes of generators must be installed with fire protection system and coated with thermal insulation layer.

c) Wires and cables used within the filling stations must satisfy following requirements:

- Wires and cables must use copper conductor and be insulated by synthesized plastic.

- Cables must conform to technical requirements according to applicable National Technical Regulation.

- Underground cables must have copper conductor and be insulated by synthesized plastic which is petrol-resistant and protected by steel cover.

- In case underground cables are not covered in steel for protection, place the cables in steel tubes (where automobiles and motorcycles passing by above) or plastic tubes (where no automobiles and motorcycles passing by above) or in separate covered trenches filled with sand.

Do not place cables in the same trenches in which fuel transmission lines are placed.

- Cables must be placed underground when they are installed across driveways, work items and intersecting with fuel transmission lines, in this case, the cables must be placed in steel tubes whose ends must protrude 0.5 m from edges of structures.

- In a single cable tube, do not place power transmission cables and lighting cables in the same place with operational cables, information cables and signal cables.

- Tubes containing cables must be connected with each other by screw thread. When connecting or branching wires and cables, use explode-proof wire separators and wire connectors.

d) Cables used for automatic devices and communication devices must comply with regulations under Point c Clause 1 of this Article.

dd) Devices installed at Z0 and Z1 hazardous zone must be explode-proof.

e) Install direct strike lightning protection system for work items within the filling stations.

Grounding system of direct strike lightning protection system must have grounding resistance no more than 10 W. Lightning arresters must be positioned at an elevation that can cover breather valves. In case breather valves are not included in lightning protection range of surrounding tall structures, install direct strike lightning protection for breather valves by lightning arresters bonded in an equipotential manner. The tip of a lightning arrester must be at least 5 m away from breather valves.

g) In order to satisfy surge and static protection, each steel tank must be welded with at least 2 metal wires connected with surge and static protection grounding system. Grounding resistance of this system must not exceed 10 W.

h) Install grounding devices for static protection of fuel transportation in positions where fuel is loaded into tanks.

i) Safety grounding system must have grounding resistance no more than 4 W. All neutral metallic components of electrical equipment and fuel dispensers must be grounded safely.

- This grounding system must be positioned at least 5 m away from direct strike lightning protection (distance calculated on the ground).

- If safety grounding system is connected with direct strike lightning protection, grounding resistance must not exceed 1 W.

k) Lightning protection and grounding design of petrol filling stations must conform to applicable regulations on lightning protection construction and design for petroleum storage.

2. Regarding floating petrol filling stations

a) Safety requirements in design, installation and use of electrical equipment in filling stations must conform to TCVN 5334:2007.

b) In case power generators are used in petrol filling stations, position the generators outside of hazardous zones. Exhaust pipes of generators must be installed with fire protection system and coated with thermal insulation layer. Areas where power generators are installed must be separated from tanks, storage or points-of-service.

c) Wires and cables used within the filling stations must satisfy following requirements:

- Wires and cables must use copper conductor, be insulated by synthesized plastic and contained in tubes.

- Cables must conform to technical requirements according to applicable National Technical Regulation.

- In a single cable and wire tube, do not place power transmission cables and lighting cables in the same place with operational cables, information cables and signal cables.

- Tubes containing cables must be connected with each other by screw thread. When connecting or branching wires and cables, use explode-proof wire separators and wire connectors.

d) Cables used for automatic devices and communication devices must comply with regulations under Point c Clause 1 of this Article.

dd) Install direct strike lightning protection system for work items within the filling stations. Lightning arresters must be positioned at an elevation that can cover breather valves. In case breather valves are not included in lightning protection range of surrounding tall structures, install direct strike lightning protection for breather valves by lightning arresters bonded in an equipotential manner. Lightning protection system must be inspected on a yearly basis according to applicable regulations and law.

Article 12. Fire prevention and suppression equipment

1. Post fire prevention and suppression regulations, fire fighting regulations, fire prohibition sign and mobile prohibition in noticeable and legible places in petrol filling stations.

2. Petrol filling stations must be adequately equipped with appropriate initial fire-fighting facilities as specified under TCVN 3890:2009 Fire safety and firefighting equipment for buildings and constructions - Equipment, placement, examination and maintenance and under this Regulation.

3. Based on fire hazards of substances and materials in each work items of petrol filling stations, equip and install appropriate fire-fighting facilities.

4. Number of initial firefighting equipment and tools is specified under Schedule 6.

Schedule 6. Number of initial firefighting equipment and tools

|

Work items |

Dry powder extinguisher (piece) |

Fire blanket (piece) |

|

|

≥25 kg |

≥4 kg |

||

|

1. Tanks of levels 1 and 2 filling stations |

2 |

2 |

4 |

|

2. Tanks of level 3 filling stations |

1 |

2 |

2 |

|

3. Fuel dispensers and areas where fuel is loaded into tanks |

- |

2 |

1 |

|

4. Car wash and maintenance areas |

- |

1 (1) |

- |

|

5. Lubricant and other product sale areas |

- |

1 (1) |

1 |

|

6. Points-of-service |

- |

1 (1) |

- |

|

7. Security offices |

- |

1 (1) |

- |

|

8. Power generators and electrical substations |

1 |

2 |

- |

a) Based on specific conditions of each fill station, may replace dry powder extinguishers with foam spray extinguishers or CO2 extinguishers depending on classes of fire.

b) Number of fire extinguishers in round brackets () refers to number of reserved fire extinguishers. Reserved fire extinguishers shall be placed close together in a separate spot in a filling station.

c) Filling stations must install appropriate water containers to immediately soak blankets in case of fire.

5. Firefighting equipment must be placed in a manner that is:

a) visible.

b) accessible.

c) no obstructing exit routes, passages and other activities. >

d) away from rain, sunlight and environmental factors.

6. Only install firefighting equipment and tools satisfactory to regulations on quality.

7. Fire extinguishers may be hung on walls, pillars or placed on the floor, etc. In case fire extinguishers are hung on walls or pillars, distance from the floor to handles of such extinguishers must not exceed 1.25 m. In case fire extinguishers are placed on the floor, such extinguishers must be placed in dry areas, if fire extinguishers are placed in brackets, height of the brackets must not exceed 2/3 the height of the extinguishers. In case fire extinguishers are placed near entrance, the extinguishers must be hung or placed at least 1 m away from edges of the entrance.

8. May place firefighting equipment and tools in a scattered or clustered manner within a petrol filling station depending on fire hazards and area of premises that needs protection (in case of cluster placement, at least 2 clusters must be guaranteed).

Article 13. Water supply and drainage and environmental hygiene systems

1. Regarding above-ground petrol filling stations

a) Domestic water and water for firefighting at petrol filling stations shall be taken from public water sources, groundwater or surface water.

b) May combine pipelines that supply domestic water and water for firefighting.

c) Oil-contaminated wastewater of petrol filling stations must be gathered in separate channels whose cover is made from reinforced concrete slab with ventilation grates or steel mesh to prevent gas buildup. Install sealant pits before connecting oil-contaminated wastewater drainage channels with general water drainage systems.

d) Oil-contaminated wastewater of petrol filling stations must be processed in a manner satisfactory to QCVN 29:2010/BTNMT National Technical Regulation on wastewater of petroleum storage and filling stations before being released into the environment.

dd) Oil-contaminated tools and refuse must be classified, stored, collected, transported and processed as specified under Decree No. 38/2015/ND-CP dated April 24, 2015 of the Government on refuse and scrap management; Decree No. 40/2019/ND-CP dated May 13, 2019 of Government on amendments to a number of Articles of Decrees on elaborating to Law on Environmental Protection; Circular No. 36/2015/TT-BTNMT dated June 30, 2015 of Ministry of Natural Resources and Environment on hazardous waste management.

2. Regarding floating petrol filling stations

a) Oil-contaminated wastewater of petrol filling stations must be gathered in separate channels whose cover is firmly installed with ventilation grates or steel mesh to prevent gas buildup.

b) Oil-contaminated wastewater of petrol filling stations must be processed in a manner satisfactory to QCVN 29:2010/BTNMT before being released into the environment.

c) Install equipment to collect petroleum spilling from nozzles when pumping or loading fuel to prevent petroleum from reaching water surface. Oil-contaminated tools and refuse must be contained in airtight containers and processed as specified under Circular No. 36/2015/TT-BTNMT dated June 30, 2015 of Ministry of Natural Resources and Environment on hazardous waste management.

Article 14. Vapor recovery system

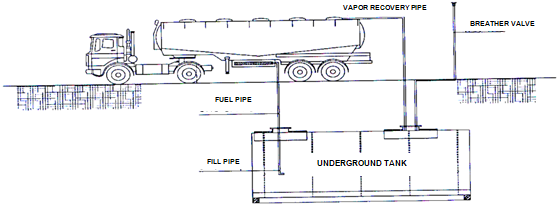

1. Illustration and working principles of a typical vapor recovery system are shown under Annex II attached to this Regulation.

2. The vapor recovery system must guarantee to completely recover petroleum gas generated during unloading process and return to tanks of fuel trucks.

3. All components of a vapor recovery system must be made from petrol-resistant and non-flammable materials.

4. General requirements for vapor recovery systems:

a) Breather valve systems of fuel tanks must satisfy regulations in this Regulation.

b) Vapor recovery nozzles of filling stations shall be installed independently similar to breather valve systems of fuel tanks.

c) Quick couplings must meet quality and airtightness requirements: rubber washers must be oil-resistant, male and female ends of quick couplings in filling stations and fuel trucks must be compatible.

d) Once the system is installed, conduct test to examine airtightness and quality of breather valves, gate valves and quick couplings of the entire system.

Article 15. Distance from petrol filling stations to other infrastructural constructions

Comply with QCVN 01:2019/BXD National Technical Regulation on construction planning.

Chapter III

REGULATIONS ON MANAGEMENT

Article 16. Responsibilities of regulatory agencies

1. Director General of Domestic Market Department – Ministry of Industry and Trade shall take charge and cooperate with relevant agencies and entities in guiding, examining and supervising implementation of this Regulation; be responsible for requesting Minister of Industry and Trade to amend this Regulation to meet practical situations.

2. Departments of Industry and Trade of provinces and central-affiliated cities are responsible for guiding, examining and supervising implementation of this Technical Regulation at a local level; receiving conformity assessment of organizations and individuals as per the law.

Article 17. Responsibilities of traders possessing petrol filling stations

1. Guarantee conformity of their petrol filling stations to this Technical Regulations and report to Departments of Industry and Trade where their petrol filling stations are situated.

2. Be subject to examination and supervision of competent regulatory agencies as per the law.

Article 18. Implementation

1. In case documents referred to in this Regulation are amended, revised or replaced, the new documents shall prevail.

2. This Regulation comes into force from January 1, 2021.

3. This Regulation replaces following national technical regulations:

a) QCVN 01:2013/BCT National Technical Regulation on design requirements for petrol filling stations;

b) QCVN 10:2015/BCT National Technical Regulation on design requirements for floating petrol filling stations.

4. Difficulties that arise during the implementation of this Regulation should be reported to the Ministry for consideration./.

ANNEX I

ILLUSTRATION AND CLASSIFICATION OF HAZARDOUS ZONES IN PETROL FILLING STATION

1. Hazardous zone

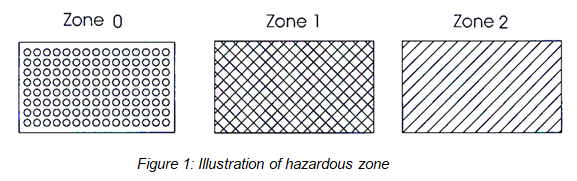

Refers to a zone in which flammable gas or liquid substances exist or may exist to create flammable/explosive environment. Hazardous zones shall be classified as follows:

- Level Z0 hazardous zone (Zone 0): refers to a zone in which flammable/explosive environment exists regularly, continuously and/or over a long period of time.

- Level Z1 hazardous zone (Zone 1): refers to a zone in which flammable/explosive environment may exist but not regularly in normal operation scenarios.

- Level Z2 hazardous zone (Zone 2): refers to a zone in which flammable/explosive environment cannot exist in normal operation scenarios or exists in a short period of time.

2. Non-hazardous zone

Refers to a zone in which flammable gas and liquid substances do not exist or cannot exist to create flammable/explosive environment. Zones situated beyond hazardous zones and not illustrated as show in Figure 1 shall be non-hazardous zone.

3. Hazardous zones in some areas in petrol filling stations

(dimensions are expressed in mm)

ANNEX II

ILLUSTRATION OF PRINCIPLE OF A TYPICAL VAPOR RECOVERY SYSTEM

Vapor recovery principle:

When fuel trucks enter parking space for unloading at petrol filling stations, connect vapor ports of the fuel trucks with vapor ports of the tanks with flexible tubes. During unloading process, petroleum is carried along flexible tubes from tanks to underground tanks of the stations, filling the empty space of the station tanks while pushing petrol vapor from the station tanks through pipes of the breather valves in the process. The vapor can be recovered by adjusting positive pressure of breather valves mounted on the fuel trucks and not releasing gas via breather valves of the station tanks. Fuel must be loaded into the station tanks in an enclosed manner.