Nội dung toàn văn Circular No. 04/2014/TT-BKHCN guiding the evaluation of production technology level

|

xMINISTRY OF

SCIENCE AND TECHNOLOGY |

SOCIALIST REPUBLIC

OF VIETNAM |

|

No.: 04/2014/TT-BKHCN |

Hanoi, April 08, 2014 |

CIRCULAR

GUIDING THE EVALUATION OF PRODUCTION TECHNOLOGY LEVEL

Pursuant to Decree No. 20/2013/ND-CP dated February 26, 2013 of the Government defining the functions, tasks, powers and organizational structure of the Ministry of Science, Science and Technology;

Implementation of national technology innovation program by 2020 approved by the Prime Minister in the Decision No. 677/QD-TTg dated May 10. 2011;

Considering the proposal of Director of Evaluation, Assessment and Inspection of Technology Department,

The Minister of Science and Technology issues Circular guiding the evaluation of manufacturing technology.

Chapter 1.

GENERAL PROVISIONS

Article 1. Scope and subjects

1. This Circular guides the contents and process of evaluation of technology level in manufacturing indutries, including: processing, fabrication, assembly and supporting industries;

2. Other agencies, enterprises, organizations and individuals involved in evaluation of technology level shall comply with the provisions in this Circular;

3. The result of evaluation of production technology level is the ground for the agencies, enterprises, organizations and individuals to propose solutions and policies to innovate and improve the production technology level of enterprises, sectors or localities;

Article 2. Explanation of terms

In this Circular, the terms below are construed as follows:

1. Production technology level is the level achieved of the production technology and is evaluated according to 04 levels: advanced, advanced average, average and backward;

2. Evaluation of production technology level is the analysis, identification of current state of technology level of enterprises or manufacturing industry based on the fixed criteria to determine the strong points and weak points of technology components to propose solutions and policies to innovate technology and improve the efficiency and production technology level of enterprises or sectors;

3. Technology contribution coefficient is the coefficient represents the technology contribution into the value-added of enterprises or sectors;

4. Manufacturing industry is the collection of enterprises producing the same group of products under level 2 sub-sector of processing and fabrication industry in the system of Vietnam economic sectors (issued together with Decision No. 10/2007/QD-TTg dated January 23, 2007 of the Prime Minister);

5. Production technology line is the system of equipment, tool and means placed or installed in line with the diagram and technology process to ensure synchronous operation to make products;

6. Number of employee is the total average employees of enterprise in the year of evaluation of technology level, not including the employees having working time of less than 03 months;

Article 3. Principles of evaluation of production technology level

1. Production technology is divided into four groups of basic component: group of technological equipment represented in the machinery, tools and means abbreviated as T (Technoware); group of human resources represented in the capacity to absorb the engineering and technology for production abbreviated as H (Humanware); group of information represented in documents and information data abbreviated as I (Infoware); group of organization and management represented in the work of organization and management abbreviated as O (Orgaware);

The evaluation of production technology level of enterprises or sectors is done on the basis of level achieved of criteria of four groups of basic component T, H, I, O.

2. The evaluation of production technology level in quantitative terms, using the common scale (100 points) to make the same level of evaluation. The classification of technology level depends on the total points achieved of criteria;

Point of criteria is determined in line with the data of survey and collection at the enterprises. The form of survey slip is specified in Annex I of this Circular;

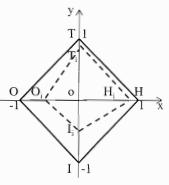

3. Technology contribution coefficient is calculated based on the points achieved of groups T, H, I, O and represents with the rhombus diagram as the grounds for remark and conclusion in the Report on result of production technology level evaluation;

4. The point of some criteria (criteria 2, 7, 8 and 16) depends much on the technology nature and characteristics of each industry and regularly changes with the social-economic development. Therefore, to determine the point of these criteria, it is necessary to rely on the comparison standard of each industry at the time of evalution;

Some criteria uniformly apply the sectoral comparison standard specified in Annex II of this Circular. On the basis of proposal of the Ministries and sectors concerned, the Ministry of Science and Technology shall review and adjust the comparison standard to suit the actual social and economic development of each period;

Chapter 2.

EVALUATION CRITERIA OF PRODUCTION TECHNOLOGY LEVEL

Article 4. Group of criterial on technological equipment - maximum 45 points

1. Criteria 1: Level of depreciation of equipment and technology - maximum 6 points

Depreciation of equipment and technology (abbreviated as ET) is the reduced use value of ET over the time. The coefficient representing the depreciation of ET (Kh) is calculated by the following formula:

![]()

In which:

- Gbđ is the initial total value of ET (primary cost);

- Gsx is the current total value of ET (depreciated).

Value of ET is taken from the yearly financial statement preceding the year to perform the evaluation of technology level of enterprises;

The point of these criteria is determined as follows:

Degree of depreciation below 15% : 6 points

Degree of depreciation from 15% to less than 30% : 5 points

Degree of depreciation from 30% to less than 45% : 4 points

Degree of depreciation from 45% to less than 60% : 3 points

Degree of depreciation from 60% to less than 75% : 2 points

Degree of depreciation above 75% : 1 point

2. Criteria 2: Capital intensity of equipment and technology - maximum 3 points

Capital intensity of ET represents the invested capital in ET of enterprises. The coefficient of capital intensity of ET (Kcđ) is calculated by the following formula:

![]()

In which:

- Gsx is the current total value of ET;

- M is the total employees.

The point of these criteria is determined by the average coefficient of capital intensity of ET of each industry (Kstandard 1) is as follows:

|

- Kcd ≥ 2Kstandard 1 |

3 points |

|

- 2Kstandard 1 > Kcd ≥ Kstandard 1 |

2 points |

|

- Kcd <>standard 1 |

1 point |

3. Criteria 3: Degree of innovation of equipment and technology – maximum 5 points

Innovation of ET is the additional investment in ET to replace and upgrade the ET system of enterprises. The coefficient of ET innovation (Kdm) is calculated by the following formula:

![]()

In which:

- Gtbm is the total value of ET newly installed and operated in production within 05 years;

- Gsx is the current total value of ET

Point of these criteria is determined as follows:

Coefficient of ET innovation from 25% or more : 5 points

Coefficient of ET innovation from 20% to less than 25% : 4 points

Coefficient of ET innovation from 15% to less than 20% : 3 points

Coefficient of ET innovation from 10% to less than 15% : 2 points

Coefficient of ET innovation of less than 10% : 1 point

4. Criteria 4: Origin of equipment and technology – maximum 3 points

These criteria represent the reliability of manufacturing country or manufacturer. Where the ETs are made by the same manufacturer but in different countries, ETs shall be determined their origin from the country of registration of that manufacturer. Where there are a lot of ETs with different origins, ETs shall be determined their origin by the origin of group of main ETs of the same origin and with the greatest total value compared with the remaining group of ETs of different origins;

The point of these criteria is determined as follows:

Origin of ET from G7: 3 points

Origin of ET from developed countries or developing countries: 2 points

Origin of ET from the remaining countries: 1 point

(G7, developed countries and developing countries are classified by announcement of the International Monetary Fund - IMF).

5. Criteria 5: Degree of automation – maximum 5 points

Degree of automation represents the moderness of ET. The coefficient of automation is determined by the ratio between the value of automation equipment over the total value of ET

![]()

In which:

- Gtđh is the value of automation equipment and determined by the total value of automation equipment multiplied by the coefficient of degree of automation divided by 3 (three). The coefficient of degree of automation is determined by the survey data collected in Table B, Annex II of this Circular;

- Gsx is the current total value of ET;

The point of these criteria is determined as follows::

Coefficient of degree of automation from 90% or more: 5 points

Coefficient of degree of automation from 75% to less than 90%: 4 points

Coefficient of degree of automation from 60% to less than 75%: 3 points

Coefficient of degree of automation from 45% to less than 60%: 2 points

Coefficient of degree of automation from 30% to less than 45%: 1 points

Coefficient of degree of automation of less than 30%: 0 point

6. Criteria 6: The degree of synchronization of the ET- maximum 4 points

The synchronous ETs are the ETs (or group of ET) between the successive stages in the production line with a capacity of production and technical parameter consistent with the general capacity of production and technical parameter of the whole line. The synchronizing coefficient of ET (Kdb) is calculated by the formula:

![]()

In which:

- Gdb is the total value of synchronous ET;

- Gsx is the current total value of ET;

Where the enterprises have many different products made on multiple production lines, the synchronizing coefficient of enterprises is calculated by the average synchronizing coefficient by the value of those production lines;

The point of these criteria is determined as follows:

Synchronizing coefficient from 75% or more : 4 points

Synchronizing coefficient from 60% to less than 75% : 3 points

Synchronizing coefficient from 45% to less than 60% : 2 points

Synchronizing coefficient of less than 45% : 1 point

7. Criteria 7: The rate of energy production costs - maximum 6 points

These criteria represent the production efficiency in terms of energy use. The coefficient of energy costs (Knl) is calculated by the ratio between the total value of energy (electricity or coal, wood, gasoline, oil, ...) expended (Gnl) with a total value of manufactured products (Gsp) in the year:

![]()

The point of these criteria is determined by the average coefficient of energy cost of each industry (Kstandard 2) as follows:

|

- Knl ≤ 0,2Kstandard 2 |

6 points |

|

- 0,2Kstandard 2 <>nl ≤ Kstandard 2 |

5 points |

|

- 0,5Kstandard 2 <>nl ≤ Kstandard 2 |

4 points |

|

- Kstandard 2 <>nl ≤ 1,5Kstandard 2 |

3 points |

|

- 1,5Kstandard 2 <>nl ≤ 2,0Kstandard 2 |

2 points |

|

- Knl > 2,0Kstandard 2 |

1 point |

8. Criteria 8: Ratio of production material cost – maximum 6 points

These criteria represent the production efficiency in terms of use of raw materials. The coefficient of raw material costs (Knvl) is calculated by the ratio between the total value of raw material (all kinds of raw material) expended (Gnvl) with the total value of manufactured products (Gsp) in the year:

![]()

The point of these criteria is determined by the average coefficient of raw material cost of each industry (Kstandard 3) as follows:

|

- Knl ≤ 0,2Kstandard 3 |

6 points |

|

- 0,2Kstandard 3 <>nvl ≤ 0,5Kstandard 3 |

5 points |

|

- 0,5Kstandard 3 <>nvl ≤ 1,0Kstandard 3 |

4 points |

|

- 1,0Kstandard 3 <>nvl ≤ 1,5Kstandard 3 |

3 points |

|

- 1,5Kstandard 3 <>nvl ≤ 2,0Kstandard 3 |

2 points |

|

- 2,0Kstandard 3 <>nvl ≤ 2,5Kstandard 3 |

1 points |

|

- Knvl > 2,5Kstandard 3 |

0 point |

9. Criteria 9: Products of production line – maximum 3 points

These criteria consider the product quality of production line according to the coefficients: satisfaction of national standard and export;

The point of these criteria is determined as follows:

|

- Satisfaction of national standard and export above 50% |

3 points |

|

- Having certificate of satisfaction of national standard |

2 points |

|

- Not having certificate of satisfaction of national standard |

1 point |

10. Criteria 10: Transfer and application of technology and intellectual property – maximum 4 points

These criteria represent the technology transfer (abbreviated as TT) not accompanied with equipment, application of technological innovation (AT) and intellectual property (IP) of enterprises;

IP includes the registration of protection of IP rights and issuance of Title of protection of intellectual property right, Certificate of intellectual property or receipt of transfer of ownership or rights to use objects of industrial property through contracts.

The point of these criteria is determined as follows:

|

- Having TT, new AI and protected IP; |

4 points |

|

- Having TT and AT but unprotected IP or having AI and protected IP |

3 points |

|

- Having TT or new AI |

2 points |

|

- Other cases |

1 point |

Article 5. Group of criterial on human resources – maximum 22 points

1. Criteria 11: The percentage of employee with college and university degree or higher - maximum 4 points

These criteria represent the professional qualification and capacity of employees in enterprises. The labor rate coefficient has the college and university level or higher (H1) is determined by the following formula:

![]()

In which:

- M1 is a number of employees having college and university level or higher and being arranged work in line with their trained majors;

- M.is the total employees

The point of these criteria is determined as follows:

|

- Percentage of university or college from 20% or more |

4 points |

|

- Percentage of university or college from 10% to less than 20% |

3 points |

|

- Percentage of university or college from 5% to less than 10% |

2 points |

|

- Percentage of university or college from 2.5% to less than 5% |

1 point |

|

- Percentage of university or college of less than 2.5% |

0 point |

2. Criteria 12: Percentage of skilled worker – maximum 4 points

These criteria represent the skill of employees in the enterprises. The percentage of skilled workers of enterprises (H2) is determined by the following formula:

![]()

In which:

- M2 is the number of skilled worker of enterprises (level 5 or higher for salary scale of 6 or 7 levels, level 4 or higher for salary scale of 5 levels, the highest level for salary scale of 4 levels or less);

- Mtt is the direct total employees

The point of these criteria is determined as follows:

|

- The percentage of skilled worker from 20% or more |

4 points |

|

- The percentage of skilled worker from 10% to less than 20% |

3 points |

|

- The percentage of skilled worker from 5% to less than 10% |

2 points |

|

- The percentage of skilled worker less than 5% |

1 point |

3. Criteria 13: Qualification of management staff – maximum 2 points

These criteria represent the qualification and capacity of management staff with the percentage of management staff having university degree or higher in enterprises in accordance with management position (H3) and are determined by the following formula:

![]()

In which:

- M3 is the number of management staff with university degree or more in accordance with management position in enterprises;

- Mql is the total management staff in enterprises;

The point of these criteria is determined as follows:

|

- H3 ≥ 50% |

2 points |

|

- 50% > H3 ≥ 25% |

1 points |

|

- H3 <> |

0 point |

4. Criteria 4: Percentage of employee through traning – maximum 3 points

These criteria represent the qualification and capacity of employee directly involved in production. The percentage of employee through vocational training (H4) is determined by the formula:

![]()

In which:

- M4 is a number of employees through vocational training (6 months or more) and arranged work in line with their trained trade;

- Mtt is the direct total employees

The point of these criteria is determined as follows:

|

- H4 ≥ 80% |

3 points |

|

- 80% > H4 ≥ 50% |

2 points |

|

- 50% > H4 ≥ 20% |

1 points |

|

- H4 <> |

0 point |

5. Criteria 15: Percentage of expense for training and development research – maximum 5 points

These criteria represent the investment in training to improve the level of human resource and development research of technology and products of enterprises. The percentage of expense for training and development research (Kđt) is determined by the following formula:

![]()

In which:

- Gđt is the total expenses for training and development research;

- Gdt is the annual total revenues.

The point of these criteria is determined as follows:

|

- Kđt ≥ 3,0% |

5 points |

|

- 3,0% > Kđt ≥ 1,5% |

4 points |

|

- 1,5% > Kđt ≥ 0,5% |

3 points |

|

- 0,5% > Kđt ≥ 0,1% |

2 points |

|

- Kđt <> |

1 point |

6. Criteria 16: Labor productivity – maximum 4 points

These criteria represent the general efficiency of production activities of enterprises. Labor productivity is the average value-added created by an employee in a year (Kns) is determined by the following formula:

![]()

In which:

- Av is the total value-added;

- M is the total employees.

The point of these criteria is determined by the average labor productivity of industry (Kstandard 4) as follows:

|

- Kns ≥ 2,0Kstandard 4 |

4 points |

|

- 2,0Kstandard 4 > Kns ≥ Kstandard 4 |

3 points |

|

- Kstandard 4 > Kns ≥ 0,5Kstandard 4 |

2 points |

|

- 0,5Kstandard 4 > Kns ≥ 0,25Kstandard 4 |

1 points |

|

- Kns <>standard 4 |

0 point |

Article 6. Group of criteria on information – maximum 15 points

1. Criteria 17. Information for production – maximum 4 points

These criteria include the contents of information for production: system of technical materials, system of materials guiding the operation, system of technical norm for equipment and criteria of raw materials and products;

The point of these criteria is determined as follows:

There are all 3 contents of information for production: 4 points

There are 02 out of 03 contents of information for production: 3 points

There is 01 out of 03 contents of information for production: 2 points

The information for production is not sufficient: 1 point

2. Criteria 18: Information for management – maximum 4 points

The criteria include the contents of information for management: management system of production techniques and training; management system of product quality; system of market, customer and supplier;

The point of these criteria is determined as follows:

There are all 3 contents of information for management: 4 points

There are 03 out of 04 contents of information for production: 3 points

There are 02 out of 04 contents of information for production: 2 points

Lacking 3 contents of information for management: 1 point

3. Criteria 19: Means and techniques of information – maximum 03 points

These criteria mention the equipment of material equipment for processing and exchange of information including types of main equipment such as: telephone, fax machine, computer, local area network (hereinafter referred to as LAN), internet, ...

The point of these criteria is determined as follows:

There are sufficient basic communication facility (phone, fax, computer, LAN, internet, ...) : 3 points

Only lack of LAN or Internet: 2 points

Lack of LAN or Internet: 1 point

No basic communication facility: 0 point

4. Criteria 20: Expenses of sale and purchase, exchange and update of information – maximum 4 points

These criteria mention the extent of information update from various sources after there are technical means for processing and exchange of information. The rate coefficient of information expense (Ktt) is determined by the total value of information expense on the total revenues:

![]()

In which:

- Gtt is the total information expense (including the charges of phone, Internet… )

- Gdt is the total annual revenues

The point of these criteria is determined as follows:

Rate of information expense from 0.25% or more: 4 points

Rate of information expense from 0.05% to less than 0.25%: 3 points

Rate of information expense from 0.01% to less than 0.05%: 2 points

Rate of information expense of less than 0.01%: 1 point

Article 7. Group of criteria on organization and management – maximum 18 points

1. Criteria 21: Management of equipment effectiveness – maximum 5 points

These criteria represent the efficiency of organization and management in enterprises. The effectiveness index of general equipment (Ktbtt) is the product of equipment effectiveness (H) and the percentage of product meeting the quality standard (Q):

![]()

In which:

- Ptt is the total products actually made;

- P is the total design capacity;

- Gđ is the total value of product meeting the standard;

- Gsp is the total value of products made.

The point of these criteria is determined as follows:

|

- Ktbtt ≥ 75% |

5 points |

|

- 75% > Ktbtt ≥ 60% |

4 points |

|

- 60% > Ktbtt ≥ 45% |

3 points |

|

- 45% > Ktbtt ≥ 30% |

2 points |

|

- 30% > Ktbtt ≥ 15% |

1 point |

|

- Ktbtt <> |

0 point |

2. Criteria 22: Development and innovation of products – maximum 4 points

These criteria

![]()

In which:

- Gspm is the total value of products innovated;

- Gspnt is the total value of products made in the previous year;

- Gsptt is the total value of products consumed;

- Gsp is the total value of products made;

The point of these criteria is determined as follows:

Development and innovation index of product from 15% or more: 4 points

Development and innovation index of product from 5% to less than 15%: 3 points

Development and innovation index of product from 1% to less than 5%: 2 points

Development and innovation index of product of less than 1%: 1 point

3. Criteria 23: Development strategy – maximum 2 points

These criteria consider the development strategy of products, markets, manpower and technology;

The point of these criteria is determined as follows:

There are sufficient development strategies: 2 points

There is not sufficient development strategy: 1 point

4. Criteria 24: Production management system – maximum 3 points

These criteria consider the level of perfection of organization – production management: formulating, applying being issued with certificate of management system in accordance with ISO 9001 standard or HACCP, SA 8000, GMP,...by the certification organization that has registered its areas of operation as prescribed;

The point of these criteria is determined as follows:

Having been issued with ISO 9001 or HACCP, SA 8000, GMP certificate,...

Having developed and applied in accordance with ISO 9001 or HACCP, SA 8000, GMP, ... but not certified;

Having production management system but not applied in accordance with ISO 9001 or HACCP, SA 8000, GMP,...

5. Criteria 25: Environmental protection – maximum 4 points

These criteria mention the capacity of environmental protection;

The point of these criteria is determined as follows:

Satisfying ISO 14001 standard: 4 points

Meeting requirements in waste treatment from 70% or more: 3 points

Meeting requirements in waste treatment from 30% to less than 50%: 1 point

Meeting requirements in waste treatment of less than 30%: 0 point

Chapter 3.

CONTENT AND PROCESS FOR EVALUATION OF PRODUCTION TECHNOLOGY LEVEL

Article 8. Evaluation of production technology level of enterprise

1. Determining the number of point of each group of technological component (T, H, I, O) and the total points of groups of technological component if enterprise under the guidance in Section 1 and Section 2, Annex III of this Circular.

2. Calculating the contribution coefficient of technology of enterprises and drawing rhombus diagram under the guidance in Section 3 and 7, Annex III of this Circular;

3. Classifying the technology level based on the total points obtained and contribution coefficient of technology of enterprises:

a) Backward technology level: contribution coefficient of technology is smaller than 0.3 or the total point of technological components is smaller than 35 points;

b) Average technology level: contribution coefficient of technology from 0.3 or more and the total point of technological components is from 35 points to less than 60 points;

c) Advanced average technological level: contribution coefficient of technology from 0.5 or more and the total point of technological components is from 60 points to less than 75 points;

d) Advanced technological level: contribution coefficient of technology from 0.65 or more and the total point of technological components is equal to or more than 75 points;

Article 9. Evaluation of production technology level of sector

1. Determining the number of point of groups of technological components (T, H, I, O), the total point of groups of technological component of manufacturing industry under the guidance in Section 4 and 5, Annex III of this Circular;

2. Calculating the contribution coefficient of technology and drawing rhombus diagram for the manufacturing industry under the guidance in Section 6 and 7, Annex III of this Circular;

3. Classifying the technology level of the manufacturing industry based on the total points obtained and contribution coefficient of technology of sector (do the same as guided for enterprises in Clause 3, Article 8 of this Circular);

4. Based on the result of classification of technology level, contribution coefficient of technology, rhombus diagram of each enterprise, make a comparison of result of other enterprises of the same manufacturing industry and make a comparison with the general result of that manufacturing sector;

Article 10. Provisions on analysis and evaluation

1. The contents specified in this Circular provide general guidelines on evaluation of production technolology level of enterprises, industries or localities. When in need of evaluation of production technolology level, the organizations shall apply the guidelines to prepare the plan for specific evaluation of production technolology level for enterprises, industries or localities;

2. When conducting the evaluation of production technolology level of industries or localities, the following steps must be carried out in turn:

a) Selecting the type of enterprise representing industry or locality;

b) Evaluating the technology level of each enterprise;

c) Evaluating the technology level of each industry on the basis of calculation and summary of result of evaluation of production technolology of enterprises of that industry;

d) Generally evaluating the technology level of locality on the basis of summary of result of evaluation of production technolology of industries of localities;

Article 11. Process of evaluation of technology level

1. Preparation work

a) Establishing group of evaluation of technology level including 03 members who have appropriate expertise and and experience in manufacturing industries of products. The group has a member as a group leader;

b) The group of evaluation of technology level shall formulate the plan for evaluation of production technology level, including the following basic contents:

- Evaluation objectives;

- Determining the manufacturing industries and the number of enterprises to be evaluated;

- Time and progress of implementation of steps;

- Estimated fund for implementation;

The determination of objectives, industries and number of enterprises that need evaluating the production technology level is carried out under the orientation of governing agencies in line with the characteristics of each industry or locality;

c) The plan for evaluation of production technology level shall be approved by the competent authority before implementation;

2. Survey and collection of data at enterprises

a) Organizing the tranining for the work of survey and collection of information and data for members of group of evaluation of technology level;

b) Sending members of the group of evaluation of technology level to the enterprises to collect information and data. The members may be divided into groups and assigned tasks in line with the actual survey and collection of information and data at enterprises;

c) Gathering data and making a survey report;

3. Analysis of evaluation

a) Gathering of survey slips from enterprises;

b) Processing information and verifying the survey data;

c) Doing some calculations, drawing diagram, classifying and making a remark about the production technology level of enterprises;

d) Doing some calculations, drawing diagram and making a remark about the production technology of each industry;

dd) Making a report on the result of evaluation of production technology level;

4. Summary

a) Meeting and making a report on the result of evaluation of production technology level;

b) Completing, sending and retain the reports and survey data;

c) Carrying out the acceptance, financial payment and finalization as prescribed;

Chapter 4.

FUNDING AND IMPLEMENTATION ORGANIZATION

Article 12. Funding for implementation

1. The funding for implementing the evaluation of production technology level of industry or locality is taken from the budget sources for science and technology and other sources legally mobilized from industry or locality

2. The contents and rate of expenditure shall comply with regulations on the norm of formulation and allocation of funding estimate for the tasks of science and technology with the use current budget on the basis of consistency with the rate of estimate of state budget annually allocated;

3. The payment and finalization of funding shall comply with the provisions of the Law on State budget and the guiding documents;

4. Where the enterprises organize the evaluation of production technology level by themselves for studying and developing the technology innovation strategy to improve their business and production capacity, the funding of evaluation shall be paid by those enterprises;

Article 13. Implementation organization

1. Based on the request of each industry, locality, periodically under the 05-year plan, the Ministries, sectors and People’s Committee of provinces and centrally-affiliated cities shall direct the implementation of evaluation of production technology level under their management and send Report on evaluation of production technology level to the Ministry of Science and Technology for summary and development of general database nation-wide;

2. Enterprised are obliged to coordinate and provide data when the Ministries, sectors or People’s Committee of provinces and centrally-affiliated cities carry out the evaluation of production technology level under the provisions of the Law on Statistics and the relevant administrative documents;

3. Technology and science organization, technology and science services provider are permitted to participate in consulting, staffing and implementing a part or signing package contract to carry out the process of evaluation of production technology level;

4. The Evaluation, Assessment and Inspection of Technology Department under the Ministry of Science and Technology shall guide, support and monitor the Ministries, sector and localities to carry out the evaluation of production technology level; develop and update the general database on the production technology level;

5. Periodically, the Ministries and sectors, under their management functions and based on the data of result of evaluation of production technology level of the previous period and the trend in technology development, shall re-determine the standard of comparison of a number of appropriate criteria for each industry and send it to the Ministry of Science and Technology for summary and uniform application on a national scale.

Article 14. Effect

1.This Circular takes effect on June 01, 2014;

2. Any problem arising during the implementation of this Circular should be promptly reported to the Ministry of Science and Technology for amendment and supplementation accordingly./.

|

|

MINISTER |

ANNEX I

SURVEY

FORM OF PRODUCTION TECHNOLOGY

(Issued together with Circular No. 04/2014/TT-BKHCN dated April 08, 2014 of

the Minister of Science and Technology)

A. GENERAL INFORMATION OF ENTERPRISE

1. Name of enterprise:

- Vietnamese: ..............................................................................................................

- English: .....................................................................................................................

- Abbreviated name: ....................................................................................................

2. Address: ..................................................................................................................

.....................................................................................................................................

3. Tel: ……………………………………………………….. 4. Fax: ...............................

5. Email: ……………………………………………………. 6. Website: ........................

7. Type of business:

|

State-owned enterprise c |

Private enterprise |

Limited liability company c |

|

Enterprise with 100% of foreign capital c |

Joint venture enterprise c |

Joint stock company c |

8. Business scale:

|

c Small |

c Medium |

c Large |

9. Business lines:

....................................................................................................................................

....................................................................................................................................

....................................................................................................................................

10. Address of production facility:

- Factory 1 ..................................................................................................................

- Factory 2 ..................................................................................................................

- Factory 3 ..................................................................................................................

11. Governing agency or parent company or company with controlling stake:

.....................................................................................................................................

.....................................................................................................................................

12. Chief Execute Officer: ...........................................................................................

13. Legal representative: ............................................................................................

B. INFORMATION OF EQUIPMENT AND TECHNOLOGY OF ENTERPRISE

|

TT |

Name of equipment & technology |

Amount Amount |

Origin |

Product yield |

Actual yield |

Power capacity (Kw) |

Production year |

Year of putting into use |

Automation level coefficient |

Primary cost (VND) |

Residual value (VND) |

||

|

Semi-automatic general purpose or special use machine |

Automatic, fixed program |

Automatic, flexible program |

|||||||||||

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

… |

……….. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total |

|

|

|

|

|

|

|

|

|

|

|

|

Note:

- Only specifying the main machinery and equipment.

- Data of equipment value are taken from the financial Statement of the year preceding the survey year.

- For a number of manufacturing industries (such as mechanics, clothing…), the machinery and equipment are general purpose machine, do not specify the capacity of designed products. For the actual capacity, specify average number of operating hours per production shift.

- Automation level coefficient of equipment is based on the regulations: equal to 1 for semi-automatic machine and general purpose and special-use machine; equal to 2 for the automatic fixed-program machine and equal to 3 for automatic flexible-program machine;

C. PRODUCTION INFORMATIONOF ENTERPRISE

|

No. |

General information |

Unit |

Amount |

Value (VNĐ) |

|

2.1 |

Manufactured products: |

|

|

|

|

|

- Name of product 1: |

|

|

|

|

|

- Name of product 2: |

|

|

|

|

|

- Name of product 3: |

|

|

|

|

|

- Other products: |

|

|

|

|

2.2 |

Exported products: |

|

|

|

|

2.3 |

Raw materials: |

|

|

|

|

|

- Raw material 1: |

|

|

|

|

|

- Raw material 2: |

|

|

|

|

|

- Raw material 3: |

|

|

|

|

|

- Other raw materials: |

|

|

|

|

2.4 |

Fuel: |

|

|

|

|

|

- Gasoline and oil: |

Kg (lít) |

|

|

|

|

- Coal and wood: |

|

|

|

|

|

- Other fuels: |

|

|

|

|

2.5 |

Total power consumption: |

Kwh |

|

|

Note:

- Only conducting a survey up to 3 products the highest revenue. Other products are included in the gross statistical value in other product categories.

- For raw material of production, only do statistics 03 main types of raw material. Other raw materials are included in the gross statistical value in other raw material categories.

- For fuel, only do statistics of gas and oil. Other fuels are included in the gross statistical value in other fuel categories.

- Value data are taken from the financial Statement of the year preceding the survey year.

D. APPLICATION OF TECHNOLOGY INNOVATION

|

No. |

Name of technology |

Research and application of new technologies |

Receipt of technology transfer |

Technology transfer contract |

|||||

|

Year |

Value |

Origin |

Year |

Technology process (Value) |

Technological know-how (Value) |

Training |

Industrial property (Value) |

||

|

1 |

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

Total |

|

|

|

|

|

|

|

|

Note:

- Value data are taken from the total cost of research and application of each technology, the value of technology transfer contract and other costs to receive the technology transfer.

- Data related to the finance are taken from the financial Statement of the year preceding the survey year.

Đ. EMPLOYMENT INFORMATION

1. Number of employee of enterprise:

|

1.1 |

Direct production |

Amount: |

Shift No.: |

|

1.2 |

Management |

Amount: |

|

|

1.3 |

Research and development |

Amount: |

|

|

1.4 |

Engineering and technology |

Amount: |

|

|

1.5 |

Other indirect production |

Amount: |

|

|

|

Total |

|

|

2. Number of workers classified by labor quality:

|

2.1 |

Appropriate qualification level: |

Amount: |

|

|

- College: |

Amount: |

|

|

- University or higher education: |

Amount: |

|

2.2 |

Appropriate managerial officials of university or higher education |

Amount: |

|

2.3 |

Workers trained with trade (including intermediate level) |

Amount: |

|

2.4 |

Skilled workers |

Amount: |

|

2.5 |

Untrained workers |

Amount: |

3. Employment cost:

|

3.1 |

Labor cost |

Value: |

|

|

- Salary |

Value: |

|

|

- Insurance |

Value: |

|

|

- Other benefits |

Value: |

|

|

Total |

|

|

3.2 |

Cost of training, research and development |

Value: |

|

|

- Cost of training |

Value: |

|

|

- Cost of research and development (R&D) |

Value: |

|

|

Total |

|

Note:

- Trained workers: only for cases of training from 06 months or more;

- Other benefits: mid-shift meal, transportation to work, vacation,…;

- Cost of research and development including the cost of equipment for analysis and control of product quality, cost of incentives, innovation of equipment, cost of improvement of product quality and development of new products…;

- Data related to finance are taken from the financial Statement of the year preceding the survey year.

E. INFORMATION ON PRODUCTION OPERATION OF ENTERPRISE

|

1 |

Design production capacity |

Amount: |

|

|

2 |

Total products made in the year |

Amount: |

Value: |

|

|

- Total products made in previous year |

Amount: |

Value: |

|

|

- Change compared with previous year |

% |

Value: |

|

3 |

Total products meeting standard in the year |

Amount: |

Value: |

|

4 |

Products damaged in the year |

Amount: |

Value: |

|

5 |

Total new products in the year |

Amount: |

Value: |

|

|

- Change of model |

Amount: |

Value: |

|

|

- Change of features |

Amount: |

Value: |

|

|

- Change of quality |

Amount: |

Value: |

|

6 |

Total products consumed in the year |

Amount: |

Value: |

|

|

- Products consumed in previous year |

Amount: |

Value: |

|

|

- Change compared with previous year |

% |

Value: |

|

7 |

Value of machinery and equipment (primary cost) |

Value: |

|

|

|

- Procurement of new machinery and equipment |

Value: |

|

|

|

- Repair of machinery and equipment |

Value: |

|

|

8 |

Residual value of machinery and equipment |

Value: |

|

|

9 |

Depreciation of assets in the year |

Value: |

|

|

10 |

Price of products |

Accounting for: % |

Value: |

|

11 |

Total revenues in the year |

Value: |

|

|

12 |

Profit before tax in the year |

Value: |

|

|

13 |

Taxes and payable to budget |

Value: |

|

|

14 |

Value-added in the year (Calculated as = Total value of V.3 + VI.9+ VI.12) |

Value: |

|

Note:

- Data in the year are taken from the financial Statement of the year preceding the survey year;

- Data of previous year are taken from the financial Statement of the year preceding the survey year one year;

- Change compared with previous year: if increased, mark (+), if decreased, mark (-)

G. INFORMATION ON MANAGEMENT AND ENVIRONMENTAL PROTECTION

1. Development strategies

|

1.1 |

Strategy of product development |

|

Yes£ |

No: £ |

|

1.2 |

Strategy of market development |

|

Yes£ |

No: £ |

|

1.3 |

Strategy of human resource development |

|

Yes£ |

No: £ |

|

1.4 |

Strategy of technology development |

|

Yes£ |

No: £ |

2. Method of management organization

|

2.1 |

Application of ISO 9001 |

With certificate £ |

Not yet £ |

|

2.2 |

Application of HACCP |

With certificate £ |

Not yet £ |

|

2.3 |

Application of SA 8000 |

With certificate £ |

Not yet £ |

|

2.4 |

Application of GMP |

With certificate £ |

Not yet £ |

|

2.5 |

Application of management standard |

With certificate £ |

Not yet £ |

3. Waster treatment

|

3.1 |

Application of ISO 14001 |

With certificate £ |

Not yet: £ |

|

3.2 |

Waste treatment |

With treatment £ |

Not yet treated: £ |

|

3.3 |

Solid treatment |

Passed % |

Treatment cost: £ |

H. INFORMATION EQUIPMENT OF ENTERPRISE

1. Material system of enterprise:

|

1.1 |

Technical material |

Sufficient: £ |

Insufficient: £ |

|

1.2 |

Operation material |

Sufficient: £ |

Insufficient: £ |

|

1.3 |

Technical norm |

|

|

|

|

- Norm of supplies and spare part for equipment |

Yes: £ |

No: £ |

|

|

- Norm of fuel for equipment |

Yes: £ |

No: £ |

|

|

- Norm of raw material for product |

Yes: £ |

No: £ |

|

|

- Norm of fuel for product |

Yes: £ |

No: £ |

2. Information system for management

|

2.1 |

Management system on production and engineering techniques |

Yes: £ |

No: £ |

|

2.2 |

Quality management system of products |

Yes: £ |

No: £ |

|

2.3 |

Management system of market and customer |

Yes: £ |

No: £ |

|

2.4 |

Information system of provider |

Yes: £ |

No: £ |

3. Information equipment:

|

3.1 |

Phone, fax, computer |

Yes: £ |

Insufficient: £ |

|

3.2 |

LAN |

Yes: £ |

No: £ |

|

3.3 |

Internet |

Yes: £ |

No: £ |

4. Information cost:

|

4.1 |

Cost of purchase, exchange information, advertising ... |

Value: |

|

4.2 |

Cost of phone, Fax, Internet |

Value: |

|

4.3 |

Cost of information equipment investment |

Value: |

|

4.4 |

Other costs of information |

Value: |

|

|

Total: |

|

ANNEX II

COMPARISON

STANDARD BY INDUSTRY

applicable to the evaluation of technology level year 2014-2015

(Issued together with Circular No. 04/2014/TT-BKHCN dated April

08, 2014 of the Minister of Science and Technology)

|

No. |

Name of processing and fabrication industry |

Code of industry |

Average capital capacity (million dong) |

Average cost of energy |

Average cost of raw material |

Average labor productivity (million dong) |

|

1 |

Production and processing of food |

C.10 |

200 |

7% |

75% |

150 |

|

2 |

Production of beverages |

C.11 |

200 |

7% |

45% |

200 |

|

3 |

Manufacture of tobacco products |

C.12 |

200 |

7% |

45% |

200 |

|

4 |

Textile |

C.13 |

200 |

7% |

65% |

100 |

|

5 |

Clothing production |

C.14 |

200 |

7% |

65% |

100 |

|

6 |

Manufacture of leather and related products |

C.15 |

200 |

7% |

65% |

100 |

|

7 |

Wood processing and making of products from wood, bamboo (except bed, cabinet, table, chairs); making of product from straw and plaiting materials |

C.16 |

200 |

7% |

65% |

100 |

|

8 |

Manufacture of paper and paper products |

C.17 |

300 |

10% |

65% |

150 |

|

9 |

Printing, photocopying of various records |

C.18 |

300 |

7% |

65% |

150 |

|

10 |

Manufacture of coke, refined petroleum products |

C.19 |

300 |

10% |

75% |

150 |

|

11 |

Manufacture of chemicals and chemical products |

C.20 |

300 |

10% |

55% |

150 |

|

12 |

Manufacture of medicine, pharmaceutical chemistry and medicinal materials |

C.21 |

300 |

7% |

60% |

200 |

|

13 |

Making of products from rubber and plastic |

C.22 |

300 |

10% |

60% |

150 |

|

14 |

Making of products from other non-metallic minerals |

C.23 |

200 |

10% |

55% |

150 |

|

15 |

Metal production |

C.24 |

300 |

10% |

65% |

150 |

|

16 |

Making of products from fabricated metal (except machinery and equipment) |

C.25 |

300 |

10% |

65% |

150 |

|

17 |

Manufacture of electronic products, computer and optical products |

C.26 |

300 |

7% |

55% |

150 |

|

18 |

Manufacture of electrical equipment |

C.27 |

300 |

7% |

65% |

150 |

|

19 |

Manufacture of unallocated machinery and equipment |

C.28 |

300 |

7% |

55% |

150 |

|

20 |

Manufacture of motor vehicles |

C.29 |

300 |

7% |

65% |

150 |

|

21 |

Manufacture of other means of transport |

C.30 |

300 |

7% |

65% |

150 |

|

22 |

Production of beds, cabinets, tables, chairs |

C.31 |

200 |

7% |

55% |

100 |

|

23 |

Other processing and manufacturing industry |

C.32 |

200 |

7% |

55% |

150 |

ANNEX III

GUIDANCE

ON DATA CALCULATION AND DRAWING OF DIAGRAM OF EVALUATION OF TECHNOLOGY LEVEL

(Issued together with Circular No. 04/2014/TT-BKHCN dated April 08,

2014 of the Minister of Science and Technology)

1. Calculating point of groups of technological component of enterprises:

![]()

In which:

i is the order of criteria of the set of criteria;

T(i) is the number point of ith criteria in group T;

H(i) is the number point of ith criteria in group H;

I(i) is the number point of ith criteria in group I;

O(i) is the number point of ith criteria in group O;

2. Calculating the total points of groups of technological component of enterprises:

t = T + H + I + O

3. Calculating the technology contribution coefficient of enterprise:

Tcc = KTbt.KHbh.KIbi.KObo

with: ![]()

bt = 0,45; bh = 0,22; bi = 0,15; bo = 0,18

- KT is the coefficient representing the degree of technology contribution of group T;

- KH is the coefficient representing the degree of technology contribution of group H;

- KI is the coefficient representing the degree of technology contribution of group I;

- KO is the coefficient representing the degree of technology contribution of group O;

- bt is the weight of intensity of technology contribution of group T;

- bh is the weight of intensity of technology contribution of group H;

- bi is the weight of intensity of technology contribution of group I;

- bo is the weight of intensity of technology contribution of group O;

Ex: After evaluating a business, the results are as follows: group of technological equipment gets 45 points; group of human resources get 11 points; group of information gets 3 points and the group of organization – management gets 16 points. We have:

- Total point of technological components of enterprise is:

t = 45 + 11 + 3 + 16 = 75 points

- The technology contribution coefficient of enterprise is:

![]()

4. Calculating point of groups of technological components of industry:

In which: - n is the total number of enterprise to be evaluated;

- Ti, Hi, Ii, Oi are the points obtained of four groups of component T, H, I, O of ith enterprise;

- Qi - Value added of products of the ith enterprise.

Ex 2: After evaluating the production industry of building materials (making products from other non-metallic minerals) of province X with the results as follow

|

No. |

Name of company |

T |

H |

I |

O |

t |

Tcc |

Q |

|

1 |

A Brick Co. Ltd |

21 |

12 |

12 |

7 |

52 |

0,51 |

47 |

|

2 |

B Brick Co. Ltd |

35 |

16 |

6 |

9 |

66 |

0,64 |

36 |

|

3 |

A Cement Joint Stock Co. |

31 |

19 |

7 |

10 |

68 |

0,66 |

149 |

|

4 |

A Tile Joint Stock Co. |

22 |

7 |

2 |

4 |

35 |

0,32 |

27 |

|

5 |

B Cement Joint Stock Co. |

37 |

13 |

6 |

9 |

65 |

0,63 |

344 |

From the above formula, we can calculate the point of groups of technological component of production industry of building materials of province X as follows:

![]()

Similarly alculating, we have: HN = 14,32; IN = 6,54; ON = 8,87

5. Calculating the total points of groups of technological groups of industry:

t(N) = TN + HN + IN + ON

6. Calculating the technology contribution coefficient of industry:

Tcc(N) = KT(N)0,45. KH(N)0,22. KI(N)0,15. KO(N)0,18

In which: ![]()

The technology contribution coefficient of industry can be calculated by the formula:

In which: - n is the total number of enterprise to be evaluated;

- Tcci is the technology contribution coefficient of ith enterprise;

- Qi is the value-added of products of the ith enterprise;

Ex 3: In the calculation in example 2, we have: the group of technological equipment gets 33.48 points; group of human resource gets 14.32 points, group of information gets 6.54 points and group of organization-management gets 8.87 points, therefore:

- The total point of groups of technological component of production industry of building materials of province X is:

t(N) = 33,48 + 14,32 + 6,54 + 8,87 = 63,20 points

The technology contribution coefficient of production industry of building materials of province X is:

![]()

= 0,740,45. 0,650,22. 0,490,15. 0,440,18 = 0,62

7. Drawing the rhombus diagram of T, H, I, O:

Four groups of technological component of T, H, I, O are represented on rectangular coordinate system. On the vertical axis oy, take a point with ordinate y = 1. The sign of that point is T. On the horizontal axis ox, take a point with coordinate x = 1. The sign of that point is T. On the vertical axis oy, take a point with ordinate y = -1. The sign of that point is I. On the horizontal axis ox, take a point with coordinate x = -1. The sign of that point is O. Connecting 4 points T, H, I, O, we get a rhombus diagram (in this case is a square) called an ideal rhombus diagram T, H, I, O.

In fact, the result of evaluation of each technological component of enterprise or product making industry in general does not reach the maximum point. Therefore, the actual quadrangle Ti, Hi, li, Oi (broken line) is totally in the ideal rhombus diagram T, H, I, O ideal (solid line).

|

Ex 4: After evaluating an enterprise (ith), the result is as follows: The technological equipment is 40 points, the human resource is 20 points, the information is 7 points, the organization – management is 12 points. The four peaks of Ti, Hi, li, Oi shall have corresponding value (without consideration of mark) are: y = KTi = 40/45 = 0,89; x = KHi = 20/22 = 0,91; -y = KIi = 7/15 = 0,47 và -x = KOi = 12/18 = 0,67 The actual quadrilateral Ti, Hi, li, Oi is represented in the figure by the broken line |

|

Compare the actual quadrangle with the ideal rhombus to remark and evaluate of the strength and weaknesse degree of each technology component.